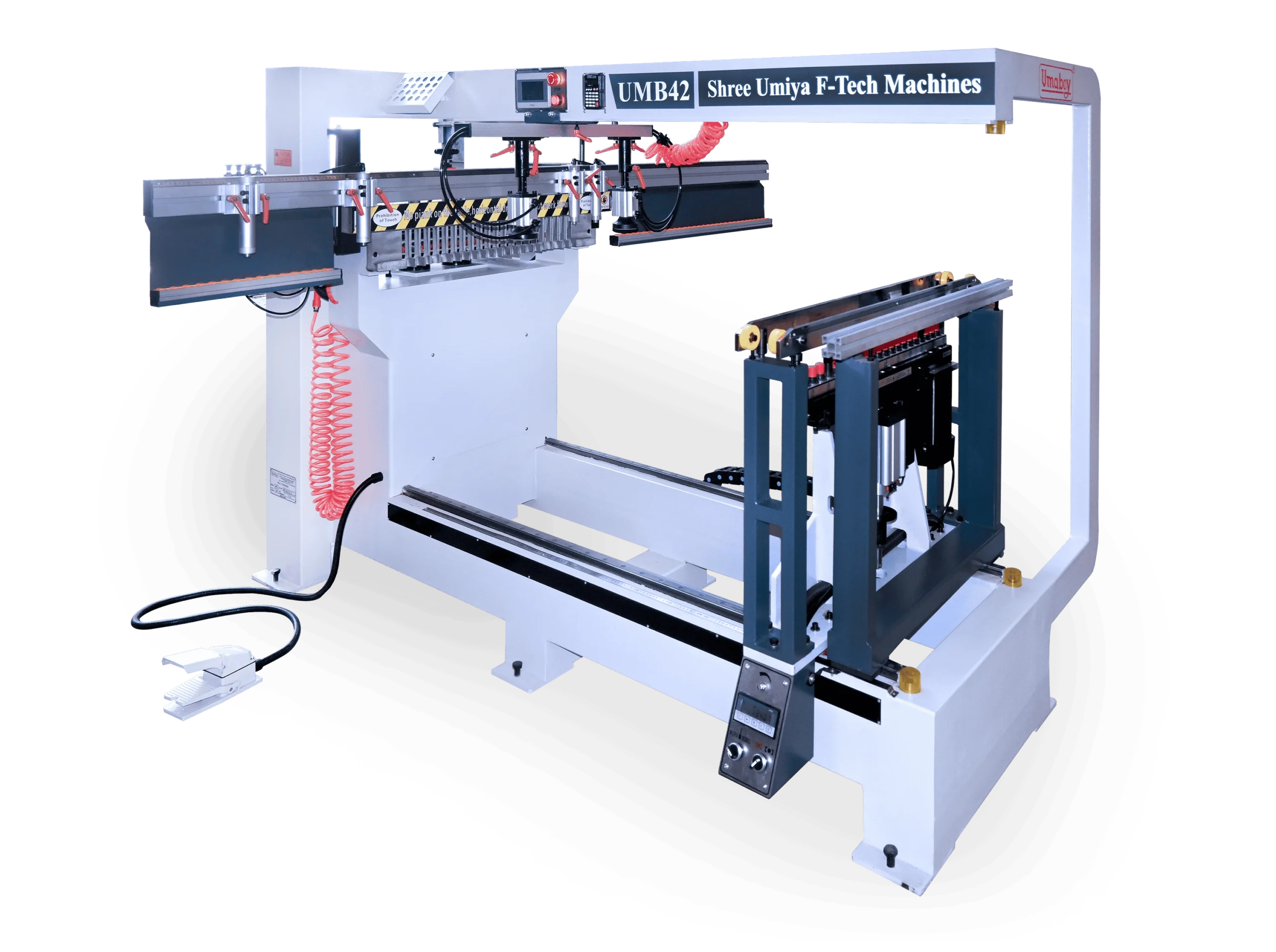

UMB 42

MULTI BORING MACHINE

PRODUCT INFORMATION DESCRIBED BELOW ↓

ULTIMATE PURPOSE MULTI DRILLING

INDUSTRIAL HEAVY DUTY SOLUTION FOR FURNITURE FACTORY

The dual-raw multi-boring machine offers precise and accurate operation. It ensures maximum precision in dowel boring with Umaboy’s high-quality drilling spindles positioned at 32mm intervals, allowing the use of drills with a maximum diameter of 35mm. Perfectly aligned rows of holes and dowel bores are assured.

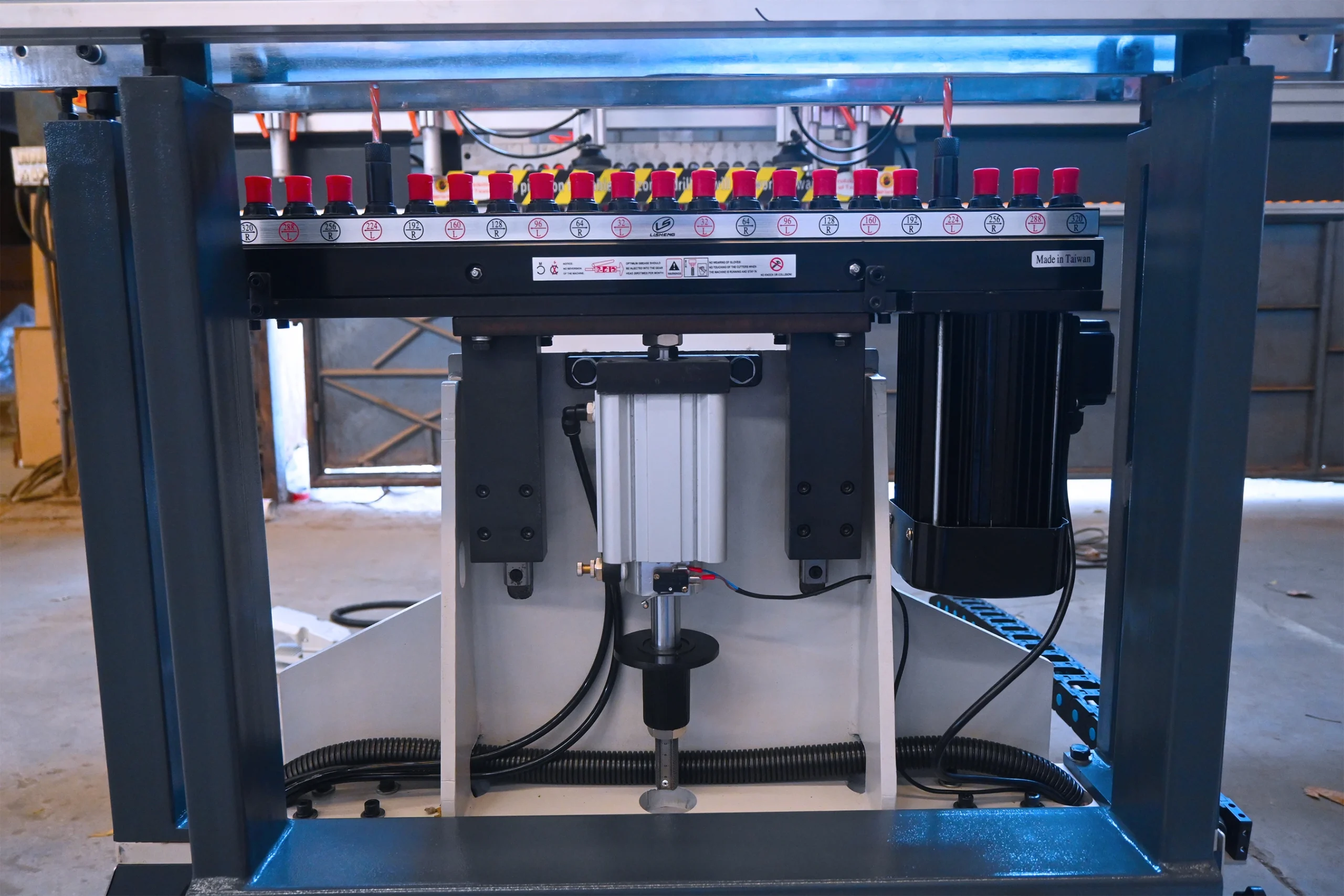

VERTICLE BORING HEAD

- To meet the requirements, 21 drilling bits are positioned at a distance of 32 mm

from each other. - Optimal power and quickness for wood drilling in assembly work

- meticulously crafted to meet the highest standards and comply with all

industry regulations.

TILTING DRILLING HEAD

- It is possible to create precise holes on both the surface and the edge of the board.

- The drilling head has the ability to tilt and move up to 90 degrees.

- The outstanding execution with precise movements and focus on the specific surface was truly impressive.

TECHNICAL SPECIFICATION

Multi Boring Machine UMB 42 Supplier in India

The dual-raw multi-boring machine offers precise and accurate operation. It ensures maximum precision in dowel boring with Umaboy’s high-quality drilling spindles positioned at 32mm intervals, allowing the use of drills with a maximum diameter of 35mm. Perfectly aligned rows of holes and dowel bores are assured. The machine features a solid steel table, sturdy fences, a pneumatic workpiece clamp, and ergonomic operating elements to guarantee top-notch quality.

As a premier Multi Boring Machine UMB 42 supplier in India, we offer top-notch machinery to meet your industrial needs with exceptional quality and service.

Salient features

- The imported original drill row, a famous & superior original electric appliance.

- The machine tool elements choose the surprise steel materials.

- The healing treatment has been conducted with great intensity.

- Accurate and convenient operation is essential for optimal performance.

Tilting Drilling Head

Can do accurate holes on the surface as well as on the edge of the board. The tilting drilling head can move 90°.

Vertical Boring Head

21 drilling bits at 32mm distance.

Technical Specifications

| TECHNICAL SPECIFICATION | |

|---|---|

| MODEL | UMB 42 |

| Distance between the bit | 32 |

| Horizontal head | 1 |

| Verticle head | 1 |

| The quantity of spindle | 42 |

| Maximum boring diameter | 35 mm |

| Maximum panel thickness | 60 mm |

| Maximum panel width | 1300 mm |

| Minimum panel width | 200 mm |

| Total Power | 3 kw |

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

See the UMB 42 in Action

🔧 Watch how the UMB 42 makes an easy process of the boring process:

- Optimal power and quickness

- Designed with 21 drilling bits for ultimate response.

- Create precise holes on both surfaces.

🎥 Click to watch the Multi Boring Function Live Demo.

Explore Our Most Selling Machines

Edge Bander

Panel Saw

Hydraulic Coldpress

Multi Boring

Urex CNC Router

Let's talk !

Please fill out this form and relax.

Our expert executive team will reach out to you and

Offer the most suitable advice according to your needs.

Please contact we would like to help you.

About Multi Boring Machine Manufacturer in India

The Multi Boring Machine UMB 42 feature and advancement

Features:

Vertical Boring Head:

To meet the requirements, 21 drilling bits are positioned at a distance of 32 mm from each other.

Optimal power and quickness for wood drilling in assembly work meticulously crafted to meet the highest standards and comply with all industry regulations.

- Tilting Drilling Head:

- It is possible to create precise holes on both the surface and the edge of the board.

- The drilling head has the ability to tilt and move up to 90 degrees.

Additional Features:- The imported original drill row, a famous & superior original electric appliance.

- The machine tool elements choose the surprise steel materials.

- The healing treatment has been conducted with great intensity.

- Accurate and convenient operation is essential for optimal performance.