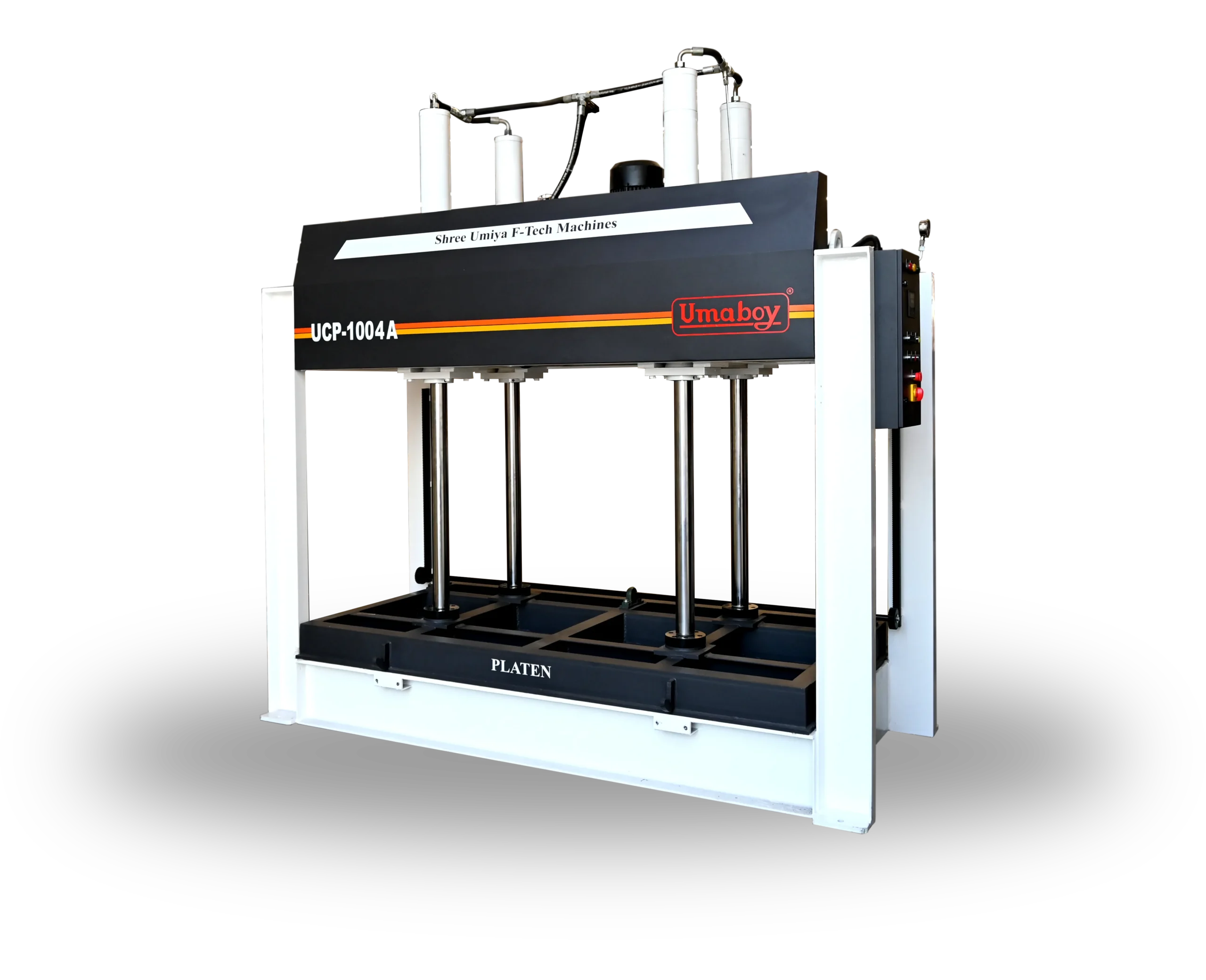

UCP 1004 A

( 4 cylinder )

HYDRAULIC COLD PRESS

PRODUCT INFORMATION DESCRIBED BELOW ↓

HYDRAULIC PRESSURE TO LAMINATION

INDUSTRIAL HEAVY-DUTY SOLUTION FOR FURNITURE FACTORY

This machine can be work with multiple types of lamination on composite wood, cork board fibre board, honeycomb board.

CONTROL PANEL

- Having a control panel makes using the machine more comfortable for the user.

- More efficient communication between the user and programming is made possible by the control panel’s display attachment.

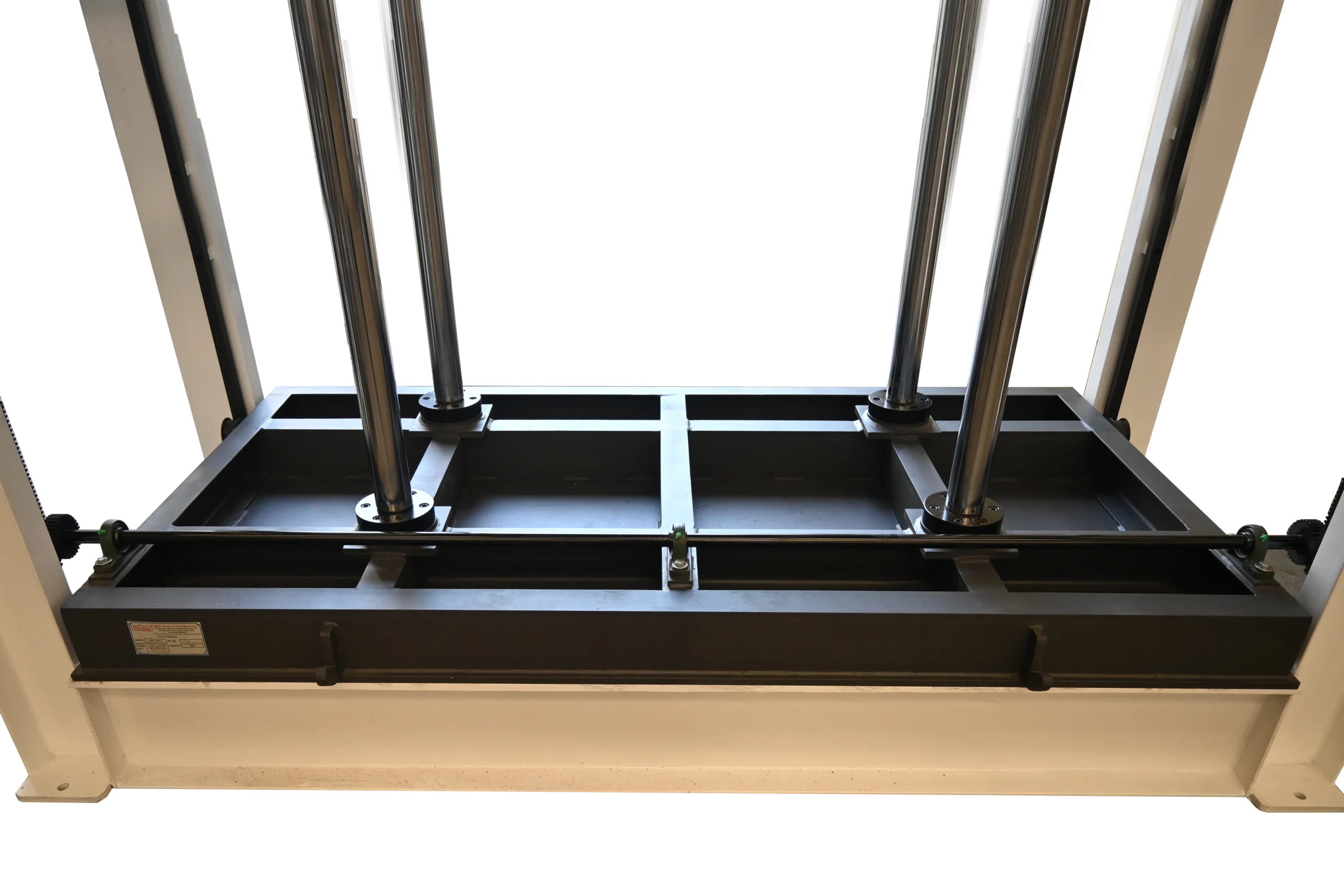

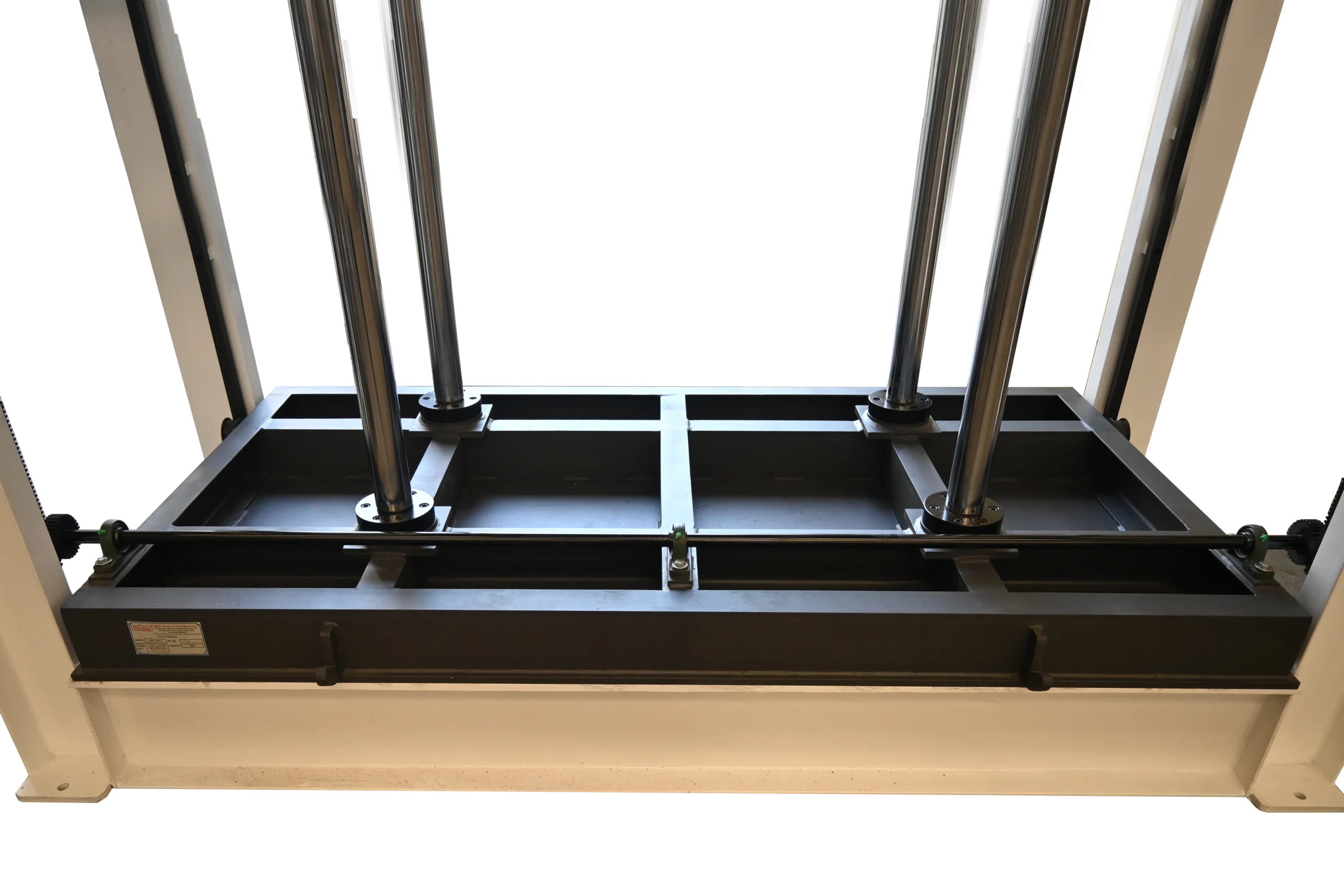

SUSPENSION PISTON

- The equipment is outfitted with a total of four high-power hydraulic cylinders, each strategically designed to deliver precise and consistent pressure performance for optimal functionality.

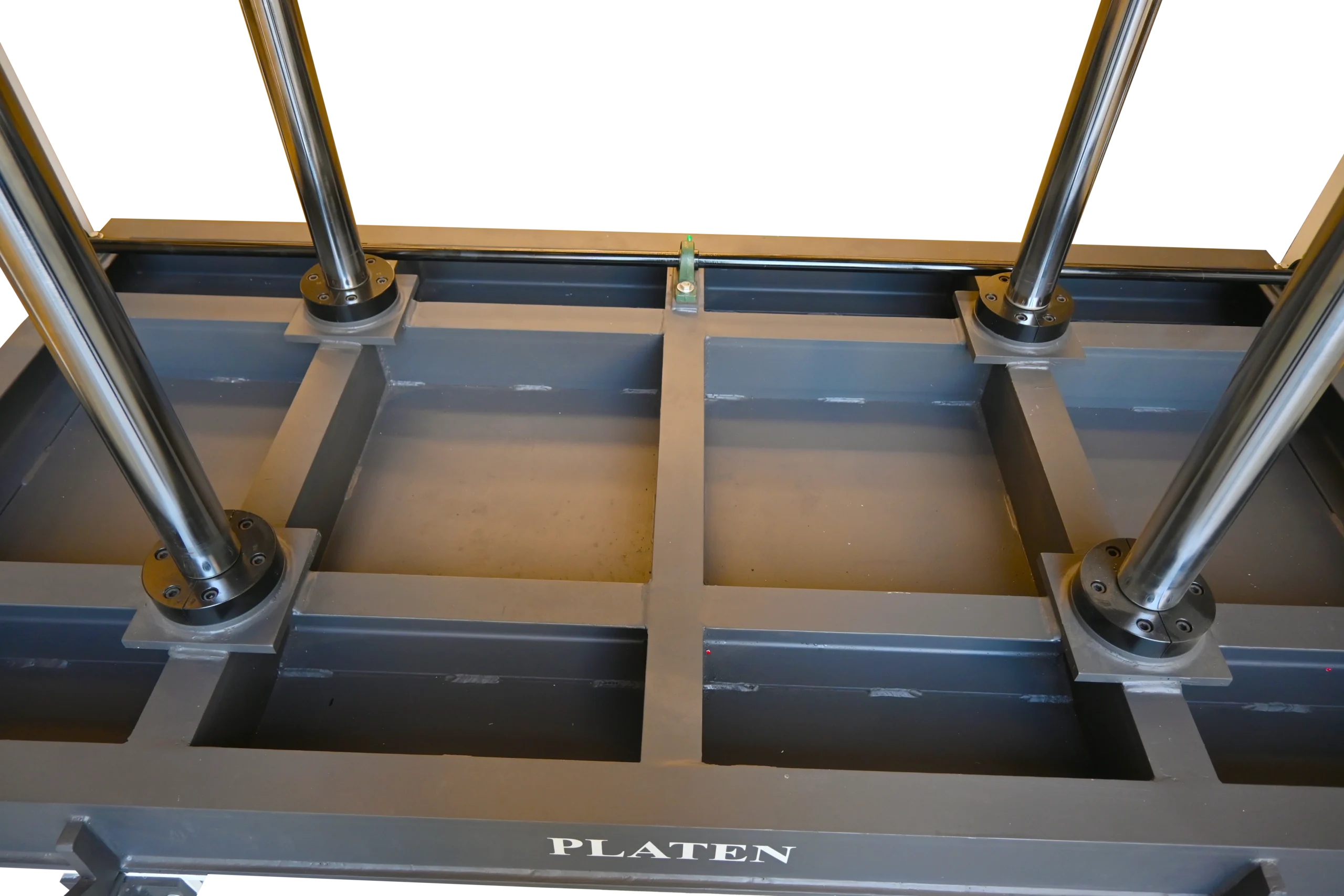

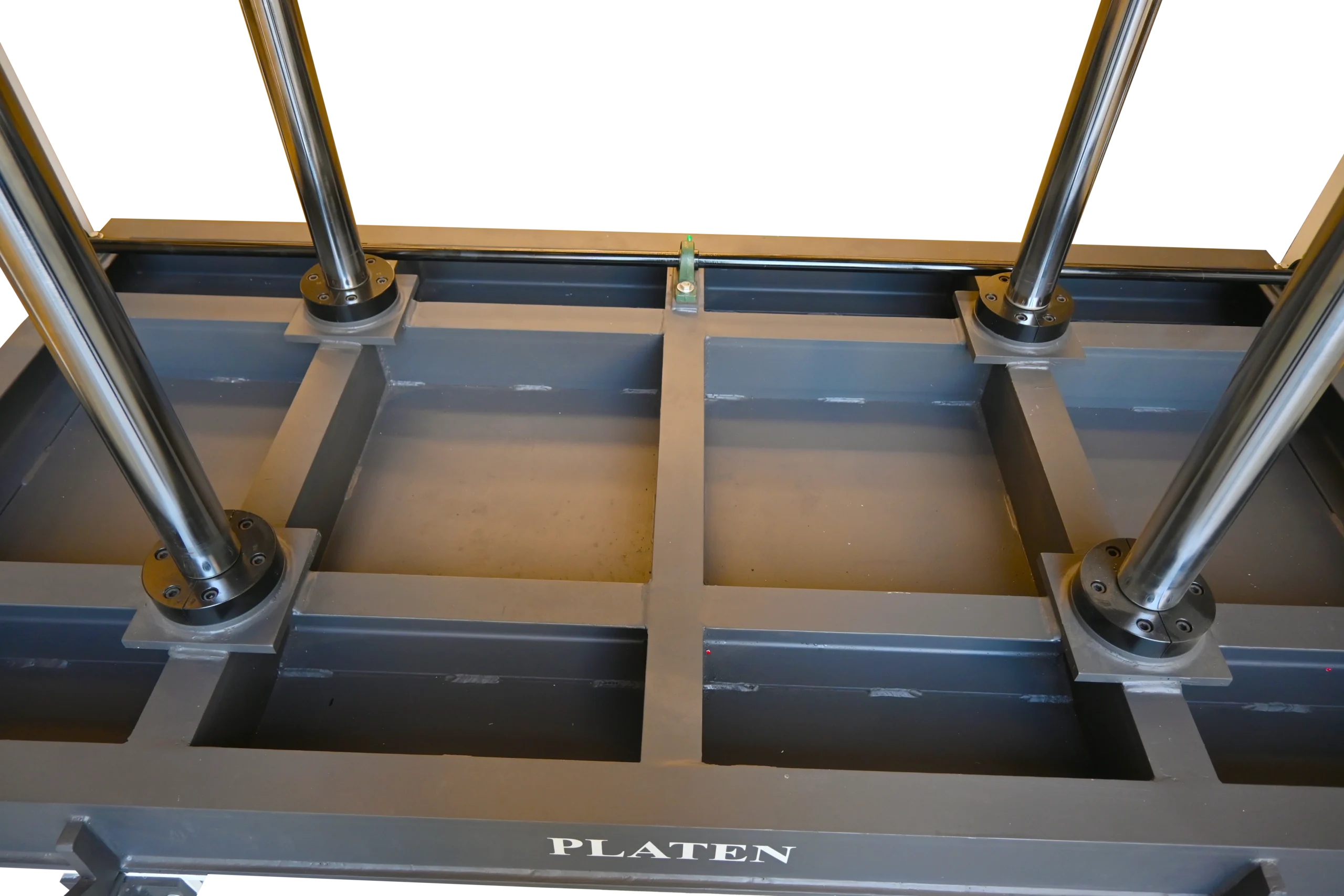

PLATTEN

- The platen is made with MS metal to guarantee durability and longevity, resulting in superior construction quality.

The planomiller process is utilized on both top and bottom platens to achieve a smooth finish and eliminate air bubbles when laminating.

PRESSURE PUMP

- A high-powered pressure pump, designed with advanced technology and precision engineering, to provide a consistent and precise transfer of pressure with consistent effectiveness and dependability.

RACK & PINION

- Precise steering response: Rack and pinion steering offers direct and responsive control, providing better handling and maneuverability.

- Compact design: The rack and pinion mechanism is more compact than other steering systems, allowing for efficient use of space in the vehicle.

TECHNICAL SPECIFICATION

Hydraulic Coldpress UCP 1004 - 4 CYLINDER

- This machine can work with multiple types of lamination on composite wood, corkboard, fiberboard, and honeycomb board.

- Having top-rate capabilities for the furniture and board lamination industry.

- I-beam welded structure for long life.

- Hydraulic cylinder with imported seals.

This cold press machine is specially designed by UMABOY to function with diverse sorts of laminations on composite wood, corkboard, fiberboard, and honeycomb board.

Technical Specifications

| TECHNICAL SPECIFICATION | |

|---|---|

| MODEL | UCP 1004 A |

| Pressure board dimensions | 2500 x 1300 mm |

| Max. pressure | 100 tons |

| Max. opening | 1000 mm |

| Power req. | 7.5 HP |

| Overall dimensions (LxWxH) | 3000 x 1450 x 3000 |

| Cylinder stroke | 1000 mm |

Explore Our Most Selling Machines

Edge Bander

Panel Saw

Hydraulic Coldpress

Multi Boring

Urex CNC Router

Let's talk !

Please fill out this form and relax.

Our expert executive team will reach out to you and

Offer the most suitable advice according to your needs.

Please contact we would like to help you.

About Hydraulic Coldpress Machine UCP 1004

The Hydraulic Coldpress Machine UCP 1004 features an advancement

I-Beam Welded Structure: Constructed with an I-beam welded structure to ensure durability and provide long-term consistent performance under high pressure.

Control Panel: Equipped with an intuitive control panel that allows for precise adjustments and monitoring of the pressing process, enhancing ease of use and operational efficiency.

High-Powered Pressure Pump: Features a powerful pressure pump capable of generating high pressure, essential for effective laminating and ensuring a strong bond between layers.

Heavy Suspension Piston: Includes a robust suspension piston designed to handle significant pressure loads, contributing to the machine’s reliability and effectiveness in laminating.

Strong Platen Frame: The strong platen frame ensures even pressure distribution across the surface, improving the quality and consistency of the laminating process.