ABOUT US

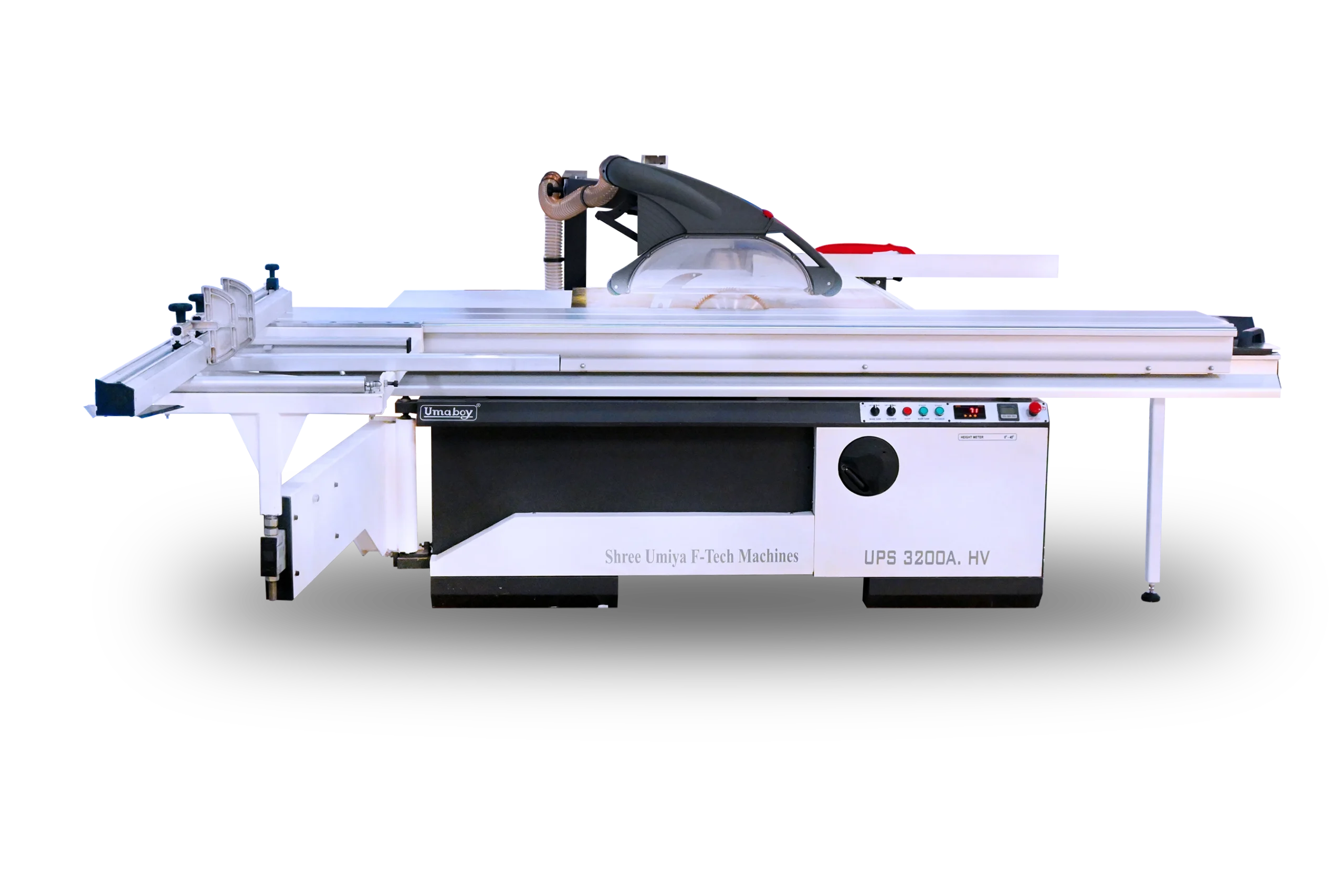

We are one of the most professional and skilled woodworking machinery manufacturing houses. We specialize in making machines for the furniture industry that can be utilized for the hardwood and modular furniture-making process.

UMABOY’s research is always fulfilled by the business requirements and helps woodworking industries to achieve new benchmarks.