UPS 3200A++

PANEL SAW WITH SLIDING TABLE

PRODUCT INFORMATION DESCRIBED BELOW ↓

HIGH PERFORMANCE CUTTING SOLUTION

INDUSTRIAL HEAVY DUTY SOLUTION FOR FURNITURE FACTORY

UMABOY specifically built this PANALE SAW Machine to conduct woodcutting with precision and attention to quality. This may work well for cutting solid wood. MDF board, laminated board, plywood, and particle board.

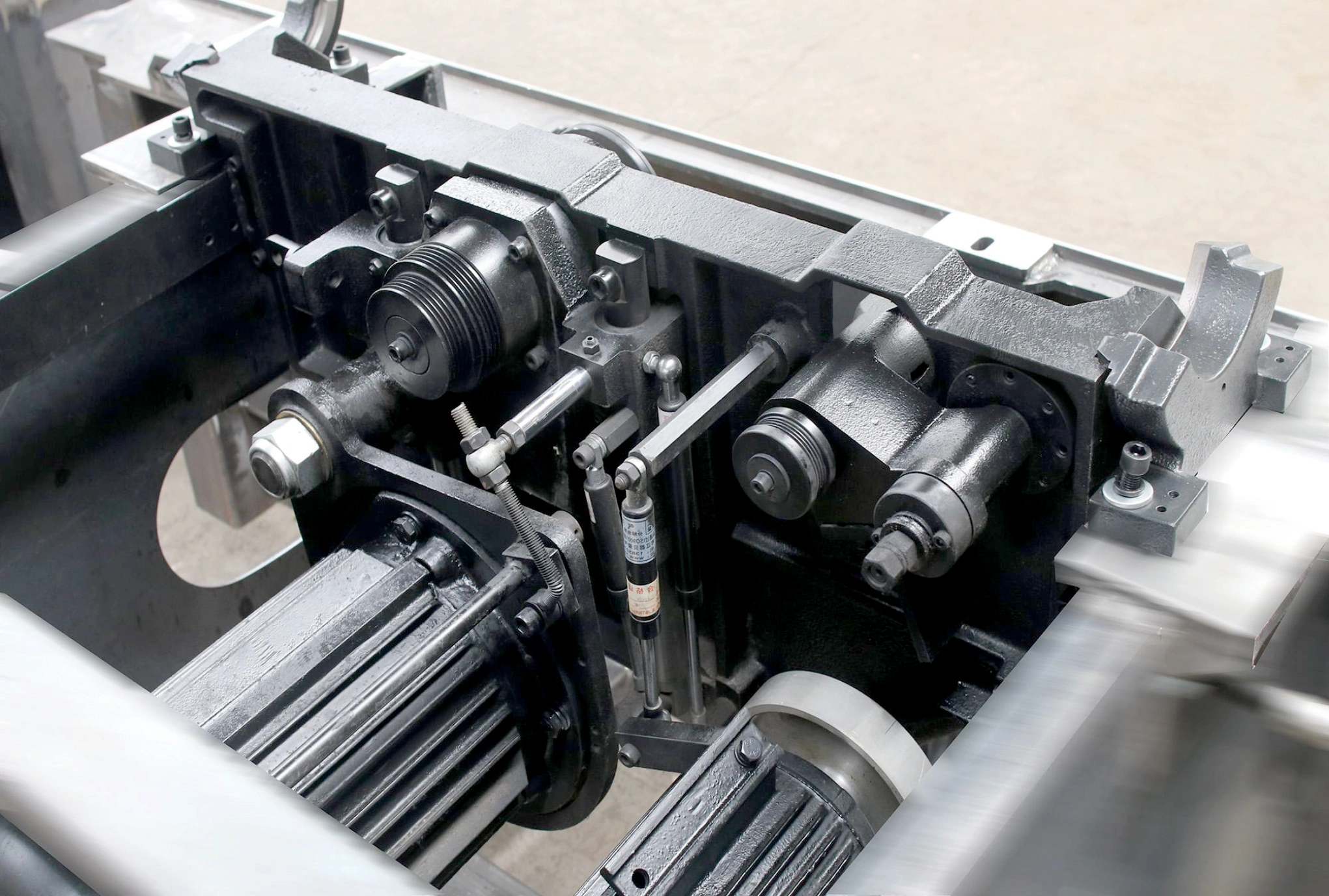

SAW UNIT

- For easy operation, smooth running with precise measurement cutting

- Machining of head is done by VMC with 5 microne preciosion.

- The system leads to vibration and noise free operation.

- Perfectly balanced housing.

N.C Controlled Rip Fence

- Error less accurate movement of rip fence

- movement can be performed by just one touch accordding tp PLC data list.

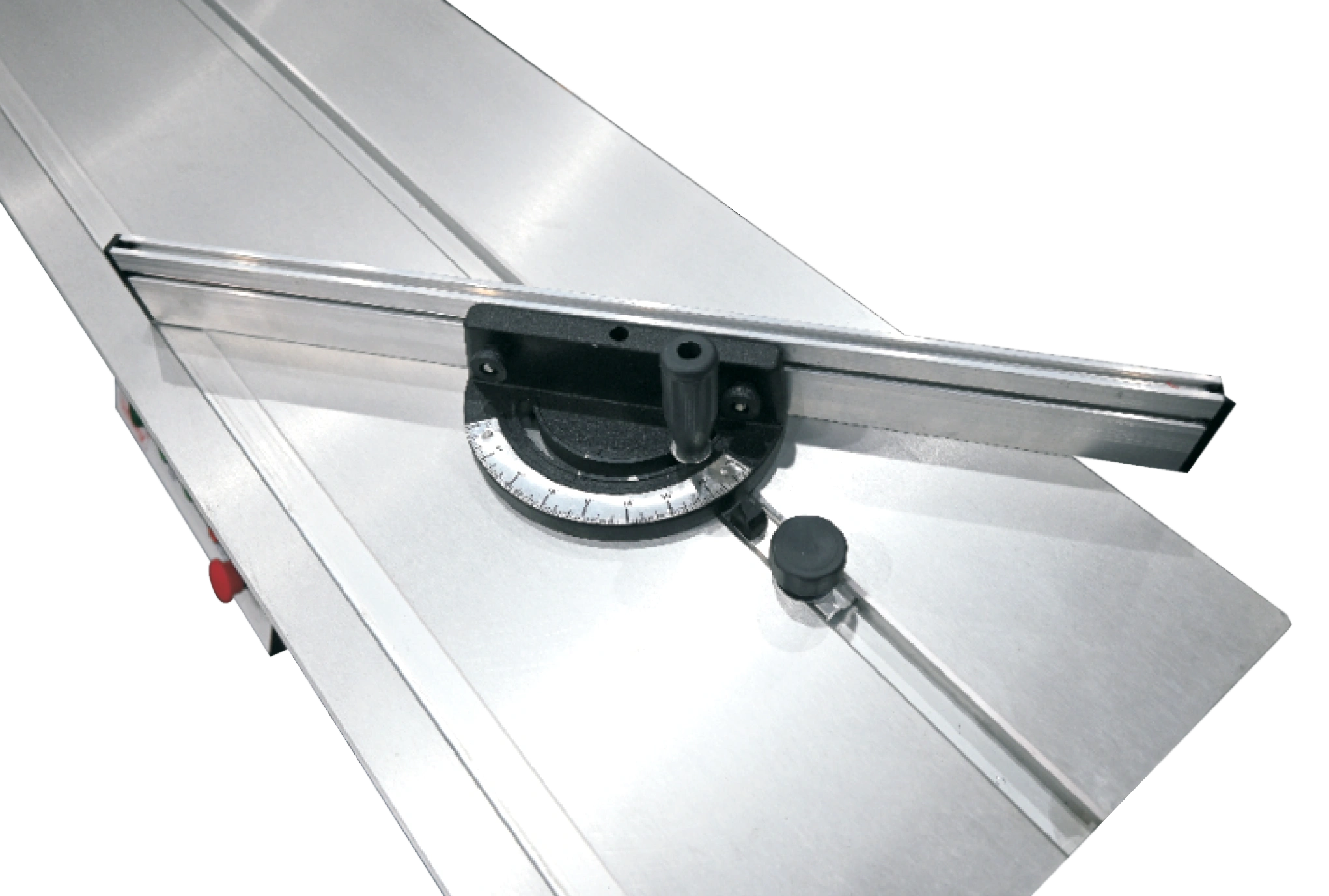

ANGLE FENCE

- Accurate angle adjustments, efficient operation, and calibration are all made possible by the precise angle meter.

- Helping to cut any type of custom size angle.

DRO Meter

- DRO meter allows for accurate measurement with digital readout.

- Leads to perfect measurements.

ELECTRIC CUTTER UP DOWN SYSTEM

- Motorized Up Down Movement for main saw cutter

and scoring cutter.

DUST COLLECTION HOOD

- Dust collection device has effective suction to accumulate all particles.

- It makes it keep away from distraction from wooden particles that were created whilst running machine

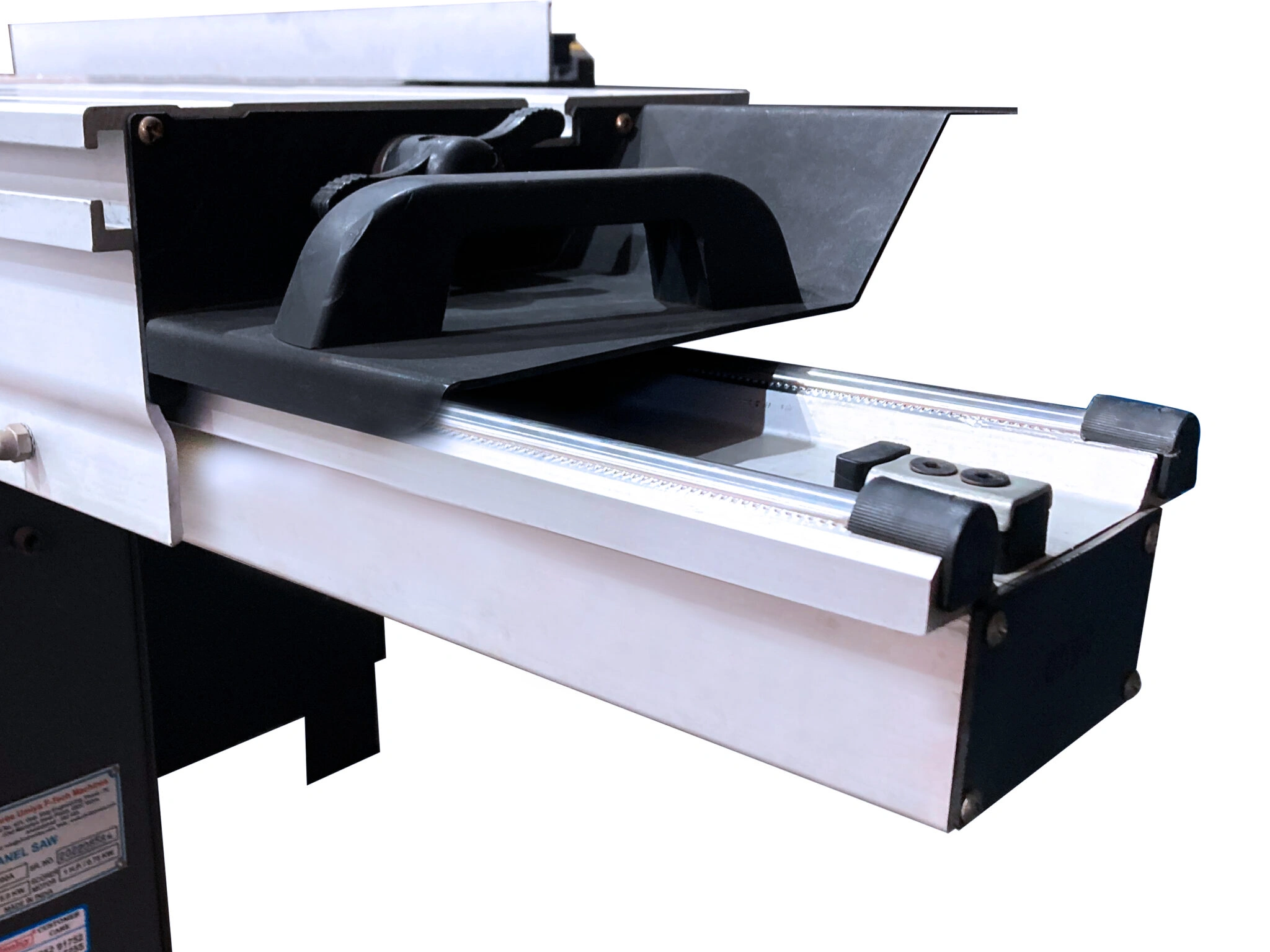

SLIDING TABLE

- Extremely smooth running and multi chamber system with linear steel bar bearing for high life.

- Double layer alluminium structure gives better strength.

- In built brush system cleans sliding road automatically.

TECHNICAL SPECIFICATION

Panel Saw UPS 3200A++

This panel saw machine is specifically built to conduct woodcutting with precision and attention to quality.

Technical Specifications

| TECHNICAL SPECIFICATION | |

|---|---|

| MODEL | UPS 3200 A++ |

| Dimension of sliding table | 3200 x 415 mm |

| Gross cut capacity | 3200 mm |

| Width of cut between saw blade and rip fence | 1220 mm |

| Saw blade diameter | 400 mm (250-400) |

| Height of cut | 125 mm |

| Height of cut ( in 45° ) | 65 mm |

| Speed of main saw spindle | 4000/6000 rpm |

| Spindle Diameter | 30 mm |

| Tilting Saw Blade | 0-45° |

| Main Motor | 5.5 kw |

| Scoring saw blade diameter | 120 mm |

| Speed of scoring saw blade | 8000 r/min |

| Scoring spindle diameter | 20 mm |

| Scoring motor | 0.75 kw |

| Overall Dimensions | 3860x3400x1400 mm |

| Rip fence movement | NC Controlled |

| 45° tilt | Motorized |

| Cross cut fence read out | Digital |

| PLC touch screen | Yes |

| Main/Scoring saw Up/Down movement | Motorized |

Explore Our Most Selling Machines

Edge Bander

Panel Saw

Hydraulic Coldpress

Multi Boring

Urex CNC Router

Let's talk !

Please fill out this form and relax.

Our expert executive team will reach out to you and

Offer the most suitable advice according to your needs.

Please contact we would like to help you.

About Panel Saw 3200A++ Machine

UMABOY specifically built the Panel Saw 3200A++ to excel in large-scale production environments. It features digital controls for precise adjustments, a high-powered motor for efficient cutting, and a heavy-structured body for stability and durability. The integrated DRO (Digital Readout) meter ensures accurate measurements, enabling high-precision wood cutting while maintaining a focus on quality. This combination of features supports both high productivity and meticulous attention to detail in demanding production settings.

The Panel Saw 3200A++ machine features and advancements

-

Digital Control Panel: Modern panel saws offer advanced measurement systems, digital readouts, and laser guides, ensuring highly accurate cuts and minimal tolerance.

-

Increased Efficiency: The digital control panel of the Panel Saw 3200A++ includes several key features to enhance its functionality and ease of use:

-

ON/OFF Switch: Allows for straightforward operation of the saw, enabling quick power control.

-

Saw Tilting Function: Facilitates precise angle adjustments for bevel cuts, ensuring accurate and versatile cutting capabilities.

-

Saw Up/Down Function: Controls the vertical movement of the saw blade, enabling adjustments for different material thicknesses and cut depths.

-

-

Digital Readouts Meter : The Panel Saw 3200A++ is equipped with a digital readout meter for perfect measurement. This feature provides precise and easily readable measurements for both saw positioning and cut dimensions. The digital readout ensures that adjustments are accurate and consistent, minimizing the risk of error and enhancing the overall precision of your woodcutting tasks. With real-time feedback on measurements, you can achieve higher quality and more accurate results in your projects.

-

Heavy Sliding Table : The Panel Saw 3200A++ features a heavy sliding table designed to handle substantial weight and demanding applications. This robust table provides stability and smooth movement, accommodating large or heavy materials with ease. Its durable construction ensures reliable performance during high-volume or intensive cutting tasks, making it ideal for professional and industrial use where precision and stability are crucial.