DISCOVER ACCURACY WITH MUILTI BORING MACHINE

UMB 42

The dual-raw multi-boring machine offers precise and accurate operation.It ensures maximum precision in dowel boring with Umaboy’s high-quality drilling spindles positioned at 32mm intervals, allowing the use of drills with a maximum diameter of 35mm. Perfectly aligned rows of holes and dowel bores are assured. The machine features a solid steel table, sturdy fences, pneumatic workpiece clamp, and ergonomic operating elements to guarantee top-notch quality.

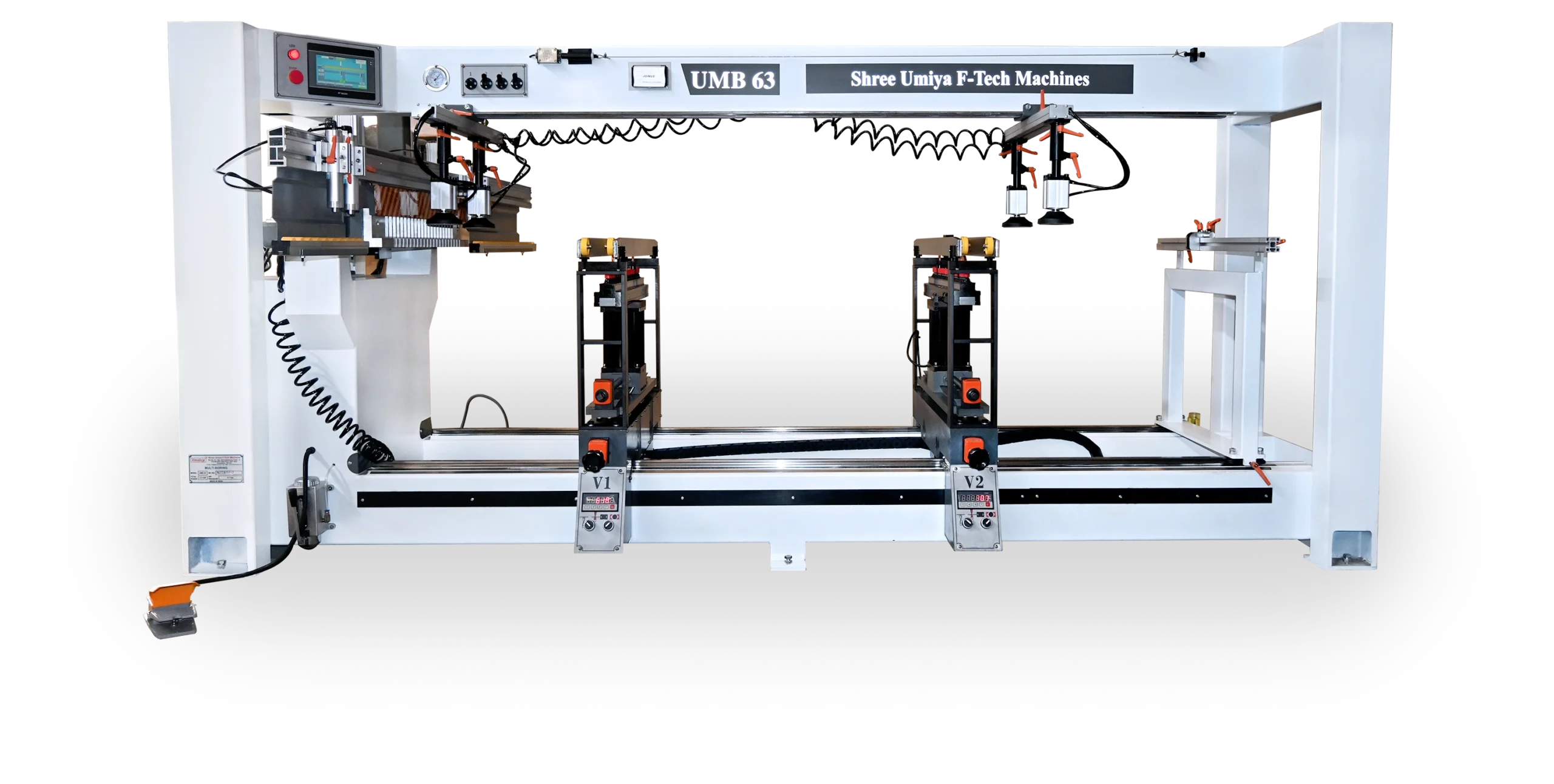

UMB 63 A

- The machine tool components choose the superior steel materials. they go through the highly and strong heat treatment

- The moving parts choose the high grade anti-wear materials,

- They are firm and durable.

- The Multi drill has been meticulously crafted, boasting a multitude of functions that operate at high speeds while maintaining exceptional precision.

- The 3-Head multi boring machine is fitted with one horizontal and two rotating vertical boring heads (0-90°), each equipped with 21 spindles. This machine is specifically designed for efficiently creating holes in a straight line for the side processing of wardrobes

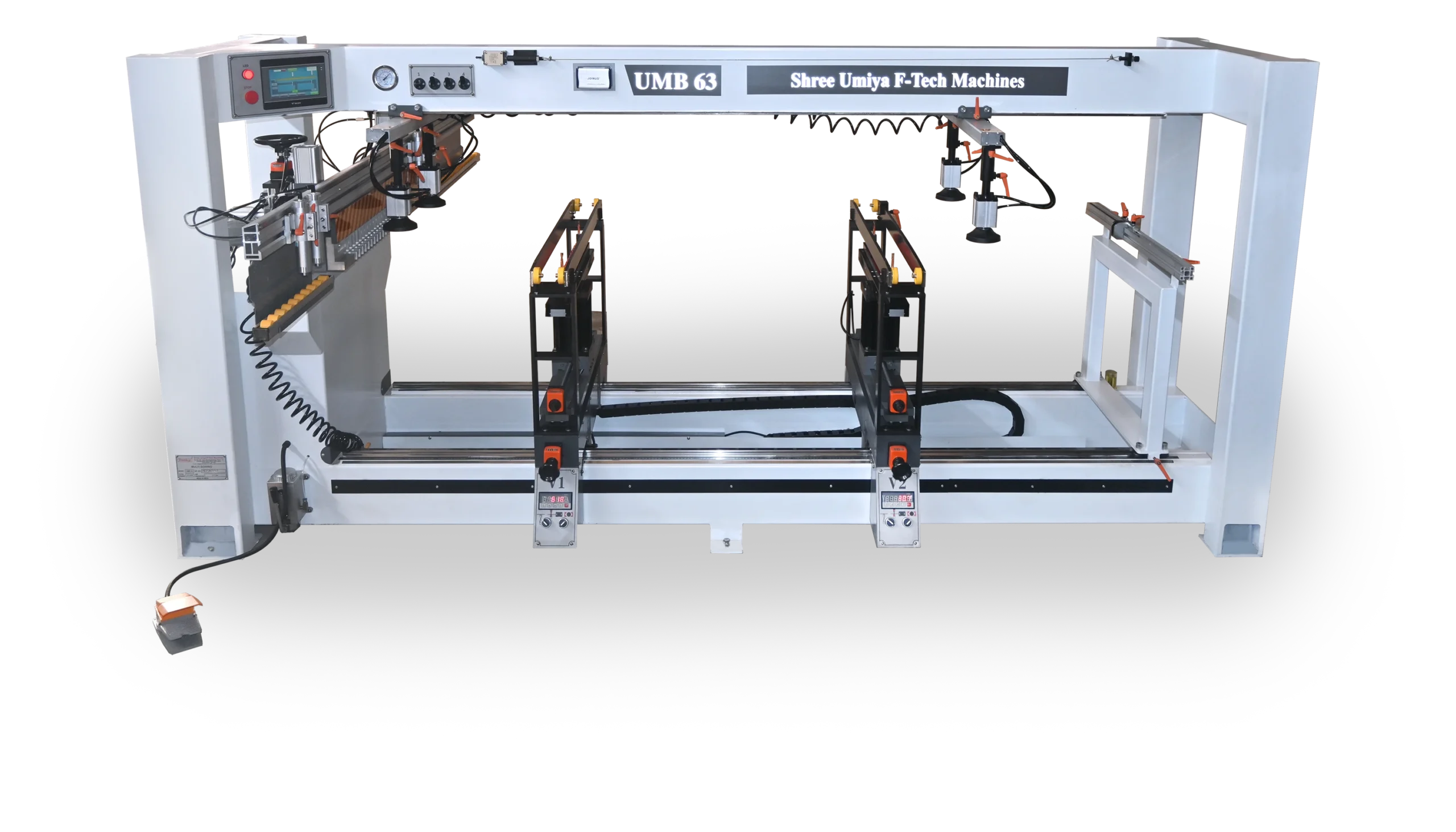

UMB 63 B

- The machine tool components choose the superior steel materials. they go through the highly and strong heat treatment

- The moving parts choose the high grade anti-wear materials,

- They are firm and durable.

- The Multi drill has been meticulously crafted, boasting a multitude of functions that operate at high speeds while maintaining exceptional precision.

- The 3-Head multi boring machine is fitted with one horizontal and two rotating vertical boring heads (0-90°), each equipped with 21 spindles. This machine is specifically designed for efficiently creating holes in a straight line for the side processing of wardrobes

Explore Our Most Selling Machines

Edge Bander

Panel Saw

Hydraulic Coldpress

Multi Boring

Urex CNC Router

About Multi Boring Machine

Multi boring machines are designed for drilling multiple holes in various configurations, enhancing efficiency in woodworking and cabinetry. They offer high precision and speed for drilling several holes simultaneously, which is ideal for mass production. Equipped with adjustable settings, these machines can handle different hole sizes and patterns, accommodating a range of material types. They significantly reduce manual drilling time and ensure consistent results across multiple workpieces. Multi boring machines are essential for tasks such as panel processing, furniture assembly, and custom woodworking projects.

The Multi Boring Machine feature and advancement

Features:

- Multiple Spindles: Allows simultaneous drilling of multiple holes, enhancing efficiency.

- Adjustable Spindle Heads: Provides flexibility for different hole sizes and spacings.

- Auto Feed Mechanism: Automates the drilling process, reducing manual effort.

- Depth Control: Ensures consistent hole depths across different materials.

- CNC Integration: Enables programmable drilling patterns for complex tasks.

Advancements:

- CNC Technology: Allows precise and programmable drilling, improving accuracy and customization.

- Improved Software: Enhanced interfaces for easier setup and operation.

- Advanced Sensors: Offers real-time monitoring and adjustments for better performance.

- Increased Speed: Modern machines drill faster and with greater efficiency.

- Enhanced Material Handling: Automated systems for better material alignment and handling.