U 1009

MANUAL EDGEBANDING

WATCH PRODUCT VIDEO

PRODUCT INFORMATION DESCRIBED BELOW ↓

MANUAL EDGEBANDING MACHINE

SMART SOLUTION FOR ENHANCE QUALITY

The machine can be performing with many different Edgebands such as PVC, ABS, veneer and acrylic On different types of boards such as plywood, chipboard, MDF/HDF..

CONTROL PANEL

- Equipped with Length counter meter for processing pre define length of panel

makes easy to operate the machine - Result can’t be meet as in line with expectation.+

- Temprature controller is displaying of glue pot temprature

- glue roller speed can be adjust according to the users by ariable speed pot.

- Micro transfer / Foot transfer each alternative are to be had for running in this

machine. ( Call upon a users )

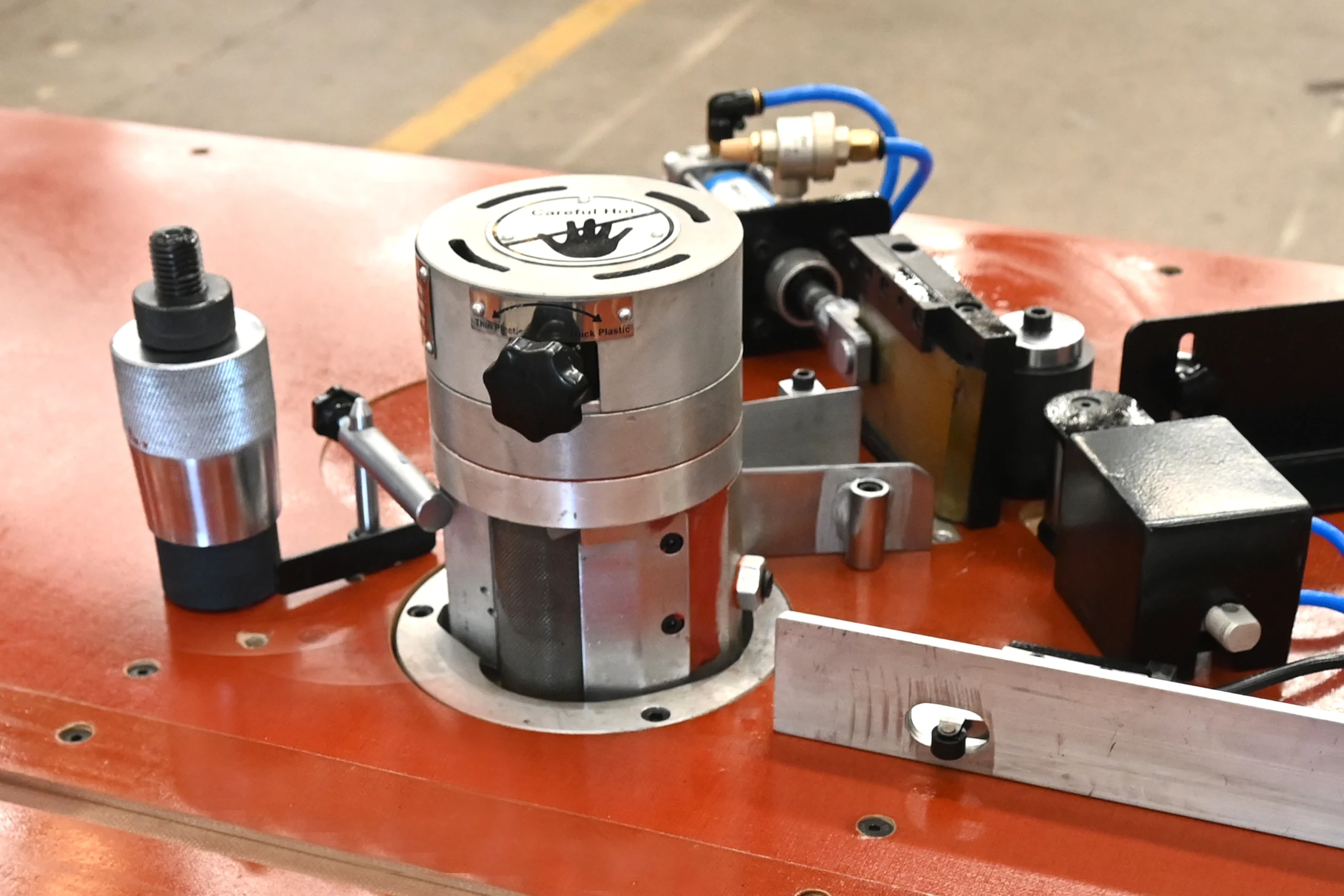

GLUE POT UNIT

- Equipped with 2.5 kg capacity of glue pot.

- For Increase and decrease Glue temprature at the glue roller is can be manage

through nobe. - Alluminium Diy casted glue pot offers an appropriate and uniform performance

in every day working.

SCISOR UNIT

- Scissor Functionality is Pneumatically Equipped with SS sharp blade to cut

edge band smoothly. - It`s Connecterd to Foot Switch and Micro Switch ( Call upon user )

Manual Edge Banding U 1009 for Sale

A large variety of construction and performance manual edgebanding machine models, including the Manual Edge Banding U 1009 for Sale, are available from Umaboy. As a leading Manual Edge Banding U 1009 Supplier in India, we offer competitive prices and top-quality options. Discover Manual Edge Banding Machine U 1009 in wholesale to meet your specific needs.

Salient Features

- Variable feed speed of edge banding.

- Alluminium glue pot with covering heat insulation material.

- Foot and micro cutting system for edge cutting.

- The top workstation is equipped with Hylam sheet.

Technical Specifications

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Explore Our Most Selling Machines

Edge Taping Machine

Edge Bander

Panel Cutting Machine

Panel Saw

Laminate Processing Machine

Hydraulic Coldpress

Multiple Drilling machine

Multi Boring

CARVING MACHINE

Urex CNC Router

About Manual Edge Banding Machine U 1009

The Manual Edge Banding U1009 machine is positioned in the economic segment, designed to offer basic edge banding functionality at a cost-effective price point.

The Manual Edge banding Machine U 1009 feature and advancement

Features:

Economic Segment Design:

- Affordability: Specifically designed to offer basic edge banding functions at a lower cost, making it an ideal choice for small businesses, startups, and hobbyists with budget constraints.

- Basic Functionality: Focuses on essential features needed for standard edge banding tasks without the advanced functionalities found in higher-end models.

- Manual Operation:

- Hands-On Control: Operates manually, allowing users to apply edge bands by hand. This approach provides flexibility for custom applications and adjustments.

- Simplified Controls: Includes basic controls for temperature and pressure adjustments, making it user-friendly and easy to manage.

Adjustable Settings:

- Temperature Control: Manual adjustment for the adhesive temperature ensures proper bonding. While not as precise as automated systems, it is sufficient for standard edge banding needs.

- Pressure Adjustment: Basic pressure controls help in applying the edge band with the correct force to ensure strong adhesion.

- Budget-Friendly: Provides a solution for edge banding at a lower price point, allowing users to manage costs effectively while still achieving reliable results.

- Value for Money: Offers good performance for basic edge banding tasks without the higher investment required for advanced machines.

Reliable Performance:

- Consistent Results: Delivers dependable edge banding for everyday tasks, ensuring a clean and professional finish for standard applications.

Ideal For:

Entry-Level Businesses: A practical choice for new or small businesses that need a functional edge banding machine without a significant financial investment.

- Consistent Results: Delivers dependable edge banding for everyday tasks, ensuring a clean and professional finish for standard applications.