MANUAL EDGEBANDING MACHINE

SMART SOLUTION FOR ENHANCE QUALITY

The machine can be performing with many different Edgebands such as PVC, ABS, veneer and acrylic On different types of boards such as plywood, chipboard, MDF/HDF..

CONTROL PANEL

- Equipped with Length counter meter for processing pre define length of panel

makes easy to operate the machine - Result can’t be meet as in line with expectation.+

- Temprature controller is displaying of glue pot temprature

- glue roller speed can be adjust according to the users by ariable speed pot.

- Micro transfer / Foot transfer each alternative are to be had for running in this

machine. ( Call upon a users )

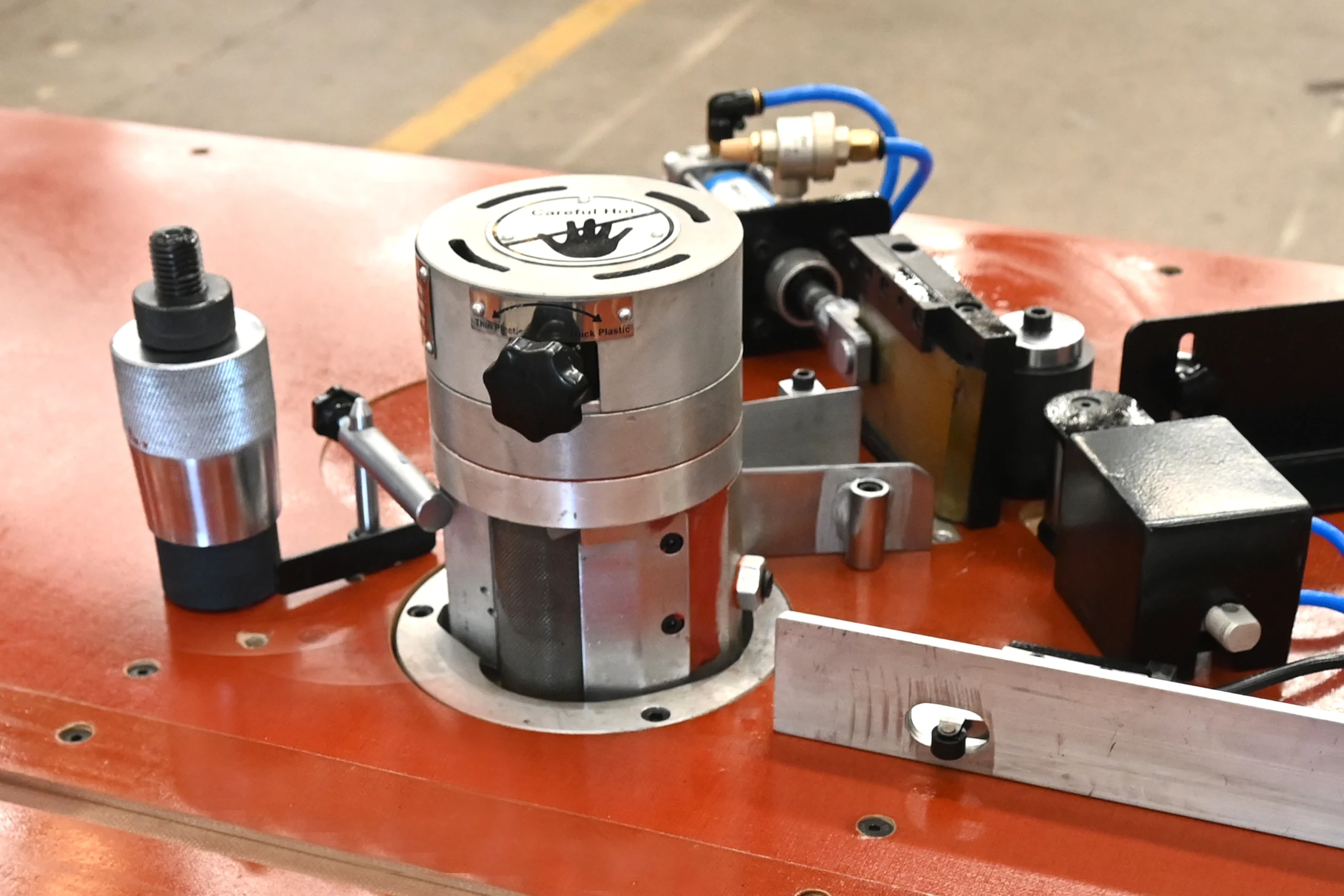

GLUE POT UNIT

- Equipped with 2.5 kg capacity of glue pot.

- For Increase and decrease Glue temprature at the glue roller is can be manage

through nobe. - Alluminium Diy casted glue pot offers an appropriate and uniform performance

in every day working.

SCISOR UNIT

- Scissor Functionality is Pneumatically Equipped with SS sharp blade to cut

edge band smoothly. - It`s Connecterd to Foot Switch and Micro Switch ( Call upon user )

SWIVEL BAR

- Extended Swivel bar is to be had for wotking in a big length of panel.

- This extendness will assist to make heavy work via way of means of easily.

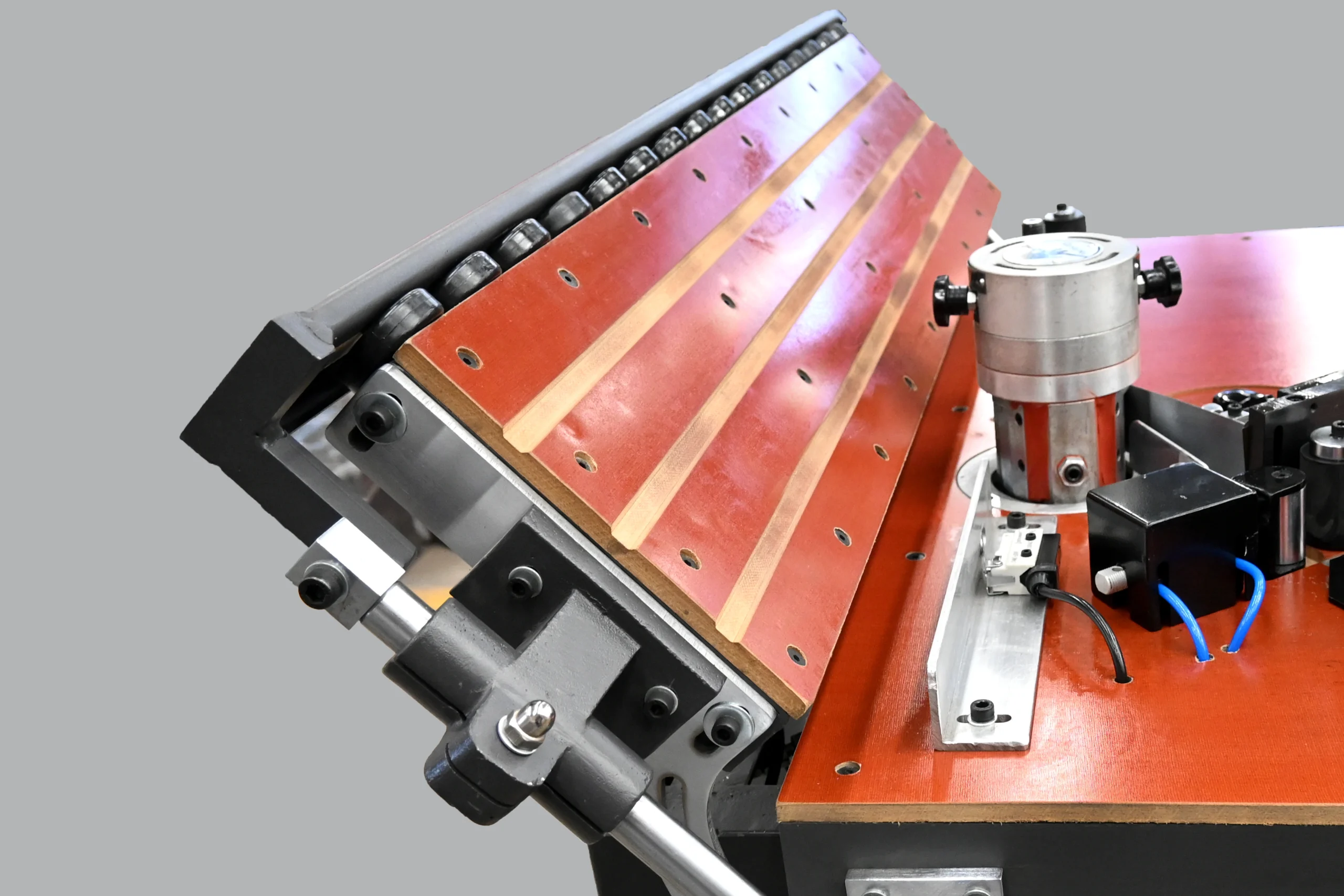

45° TILTING BAR

- Tilting desk is Equipped to apply edgeband on panel with 45° angle.

- It can be move till 45° and help to hold panel with perfect position and

get better stability. - The top workstation is equipped with Hylam sheet. which accomplished with

Heat resitant, shock proof, water proof

45° PVC EDGE BAND PRESSING UNIT

- Eqipped with 45° roller to pressing band for perfect stuck on panel

to log lastinf performance. - This rollers are one after the other symmetrically and with static position pressing edge band to straight and at 45° to make strong stuckness.

45° PVC V GROOVE UNIT

- 45° PVC V groove is fuctionning to make groove on edge band in order that

band can be stuck with panel in duck beak shape - High speed motor is equipped to V groove on band .

Manual Edge Banding U 1006-45 for Sale

Edge Banding without compromise is our motto. As a leading Manual Edge Banding U 1006-45 Supplier in India, we offer a wide selection of models. Manual Edge Banding U 1006-45 for Sale and as a trusted Manual Edge Banding U 1006-45 exporter, Umaboy meets all your edge banding needs with top-quality machines and exceptional performance.

Salient Features

- Variable feed speed of edge banding.

- Swivel bar roller support for big width work piece.

- Aluminium glue pot with covering heat insulation material.

- Foot and micro cutting system for edge cutting.

- High speed motor equipped with ‘V’ groove tool.

- 45° & Straight pressing unit

Technical Specifications

| TECHNICAL SPECIFICATION | |

|---|---|

| MODEL | U 1006 45° |

| Maximum thickness of work piece | 10 to 50 mm |

| Tape thickness | 0.4 to 2 mm |

| Glue pot capacity | 2 kgs.approx |

| Heating Element | 3 kw |

| Tape cutting mechanism | Pneumatic |

| Control of tape cutting | Micro / foot switch |

| Working speed per minute | 0 to 10 mts ( variable ) |

| Motor | 1 HP |

| Air pressure | 5 to 7 kg/cm² |

| Tape coil dia | 525 mm |

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Explore Our Most Selling Machines

Edge Bander

Panel Saw

Hydraulic Coldpress

Multi Boring

Urex CNC Router

About Manual Edge Banding U 1006-45°

UMABOY’s manual edge banding machine features a 45° PVC V-Groove unit, designed for precise edge banding with angled cuts. This unit allows for the application of PVC edge banding at a 45° angle, which is ideal for achieving clean and professional finishes on panels with beveled or angled edges. The 45° V-Groove unit enhances the machine’s versatility, making it suitable for a variety of woodworking applications where angled edge banding is required.

The Manual Edge banding Machine 1006-45° feature and advancement

-

Features:

-

The UMABOY’s Manual Edge Banding Machine U 1006-45° is equipped with several advanced features to enhance its functionality:

-

45° Tilting Table: Allows for precise angle adjustments, enabling the machine to handle edge banding tasks at a 45° angle for improved versatility and accuracy.

-

Control Panel: Provides user-friendly operation and control over various settings, making it easier to adjust and monitor the edge banding process.

-

45° V PVC Grooving Function: Facilitates the application of PVC edge banding at a 45° angle, ensuring clean and professional results on beveled or angled edges.

-

The UMABOY Manual Edge Banding Machine U 1006-45° offers several benefits that enhance its performance and usability for edge banding tasks:

Versatile Angle Adjustments: The 45° tilting table allows for precise edge banding on angled or beveled edges, increasing the machine’s versatility for various woodworking projects.

User-Friendly Control Panel: The intuitive control panel simplifies operation and adjustments, making it easier to set up and manage different edge banding tasks efficiently.

Precision Grooving: The 45° V PVC grooving function ensures accurate and clean application of PVC edge banding, providing a professional finish on angled edges.

Enhanced Accuracy: The machine’s ability to handle angled edge banding with precision reduces the likelihood of errors and ensures high-quality results.

Flexibility: Ideal for a range of woodworking applications, from small-scale projects to more detailed work, the U 1006-45° caters to different production needs.

Efficient Operation: The manual design allows for controlled and consistent application, enhancing productivity while maintaining a focus on quality.

-

-