- Home

- About Us

- Panel Processing

Panel Processing Machine

Panel Saw MachineAutomatic Edge Bander MachinesManual EdgebanderAutomatic CNC Beam SawNesting CNC RouterHydraulic Cold Press MachineHydraulic Hot Press MachineCNC Router - Solid Wood

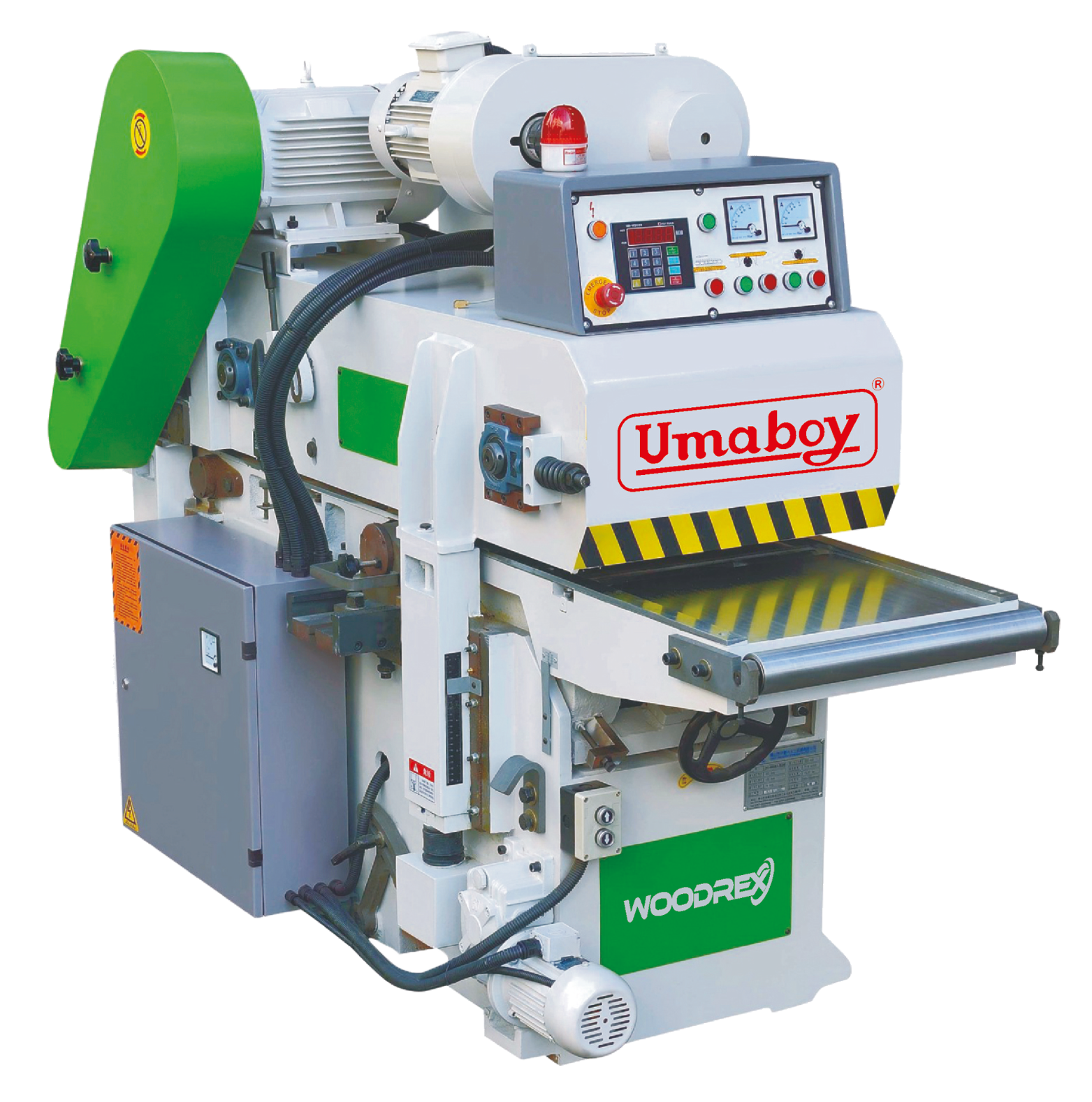

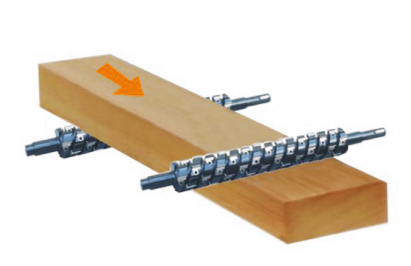

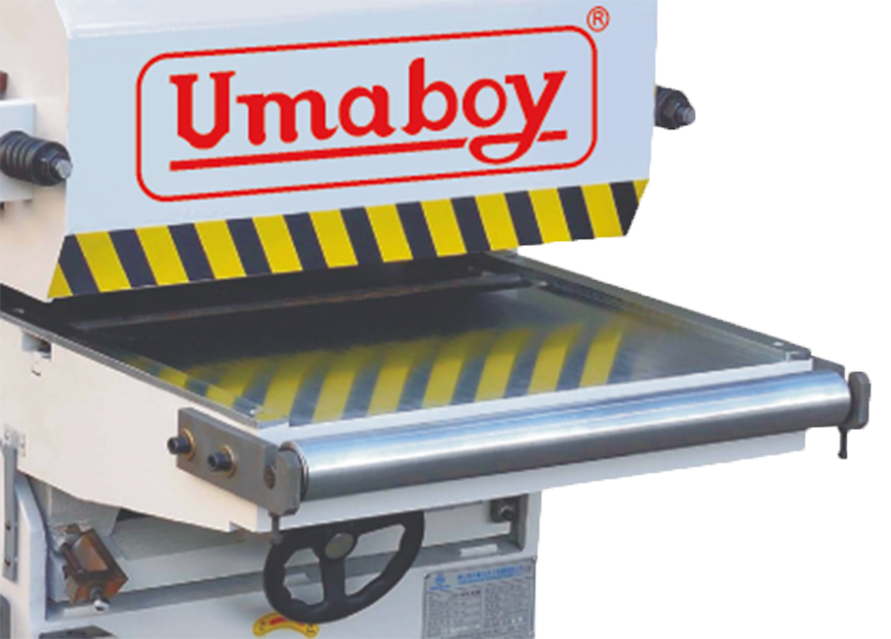

Solid Wood Machines

Wide Belt SanderClamp CarrierFinger Joint MachinesRebating MachineTenoning MachineMortiser MachinesCopy ShaperBand Saw - Blog

- Contact Us