AUTOMATIC SOLLUTION FOR DRILLING

EXCELLENCE DRILLING WITH AN AUTOMATION OBJECTIVE SOLUTION.

Enhanced processing capabilities include six-sided drilling, double-sided grooving, and milling with intelligent optimization of the processing path in the latest upgrade.

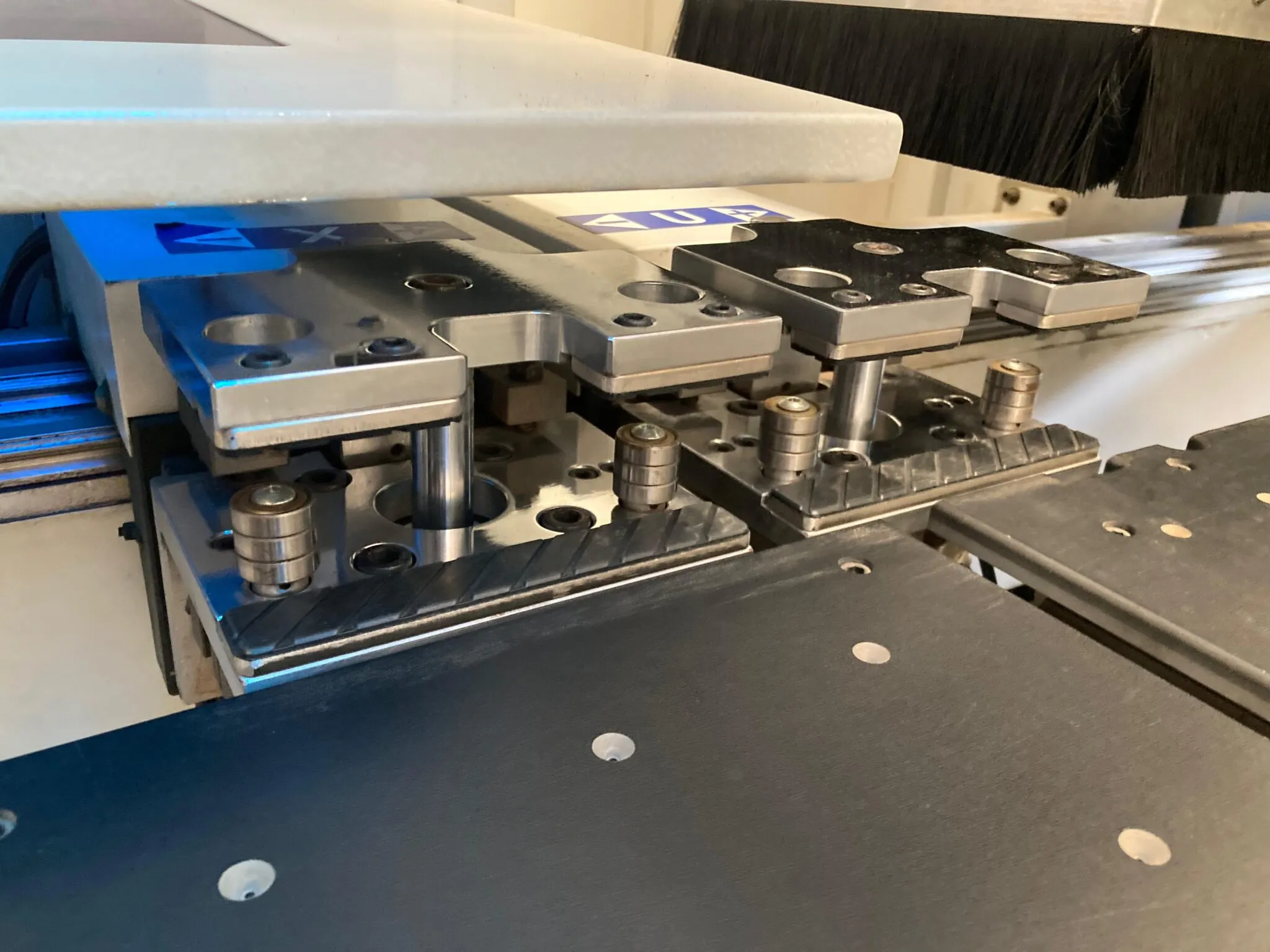

DOUBLE GRIPPER

- The double gripping hands automatically clamp the Panel for feeding into the machine, enhancing drilling accuracy by

automatically adjusting the side positioning. Additionally, the system can detect the width of the plate to prevent any errors during processing.

SERVO MOTOR

- Capable of precise positioning at a high level of accuracy

- Servo provides optimal gripper control.

- Gripping speed of motor reaches up to 80 m/min (approx.).

- It has effectively served the purpose of delivering swift and

accurate positioning. - All the instruments installed are under complete PLC control.

CONTROLLER DISPLAY

- The machine comes with complete PLC-controlled capabilities.

- control system incorporates a user-friendly Windows-based

interface, allowing for seamless interaction between man and machine. With the

ability to import drilling data using CAD software, the system ensures efficient

and convenient operations. - It seamlessly integrates with the user’s production design management

software, eliminating the need for manual input of drilling hole data.

By utilizing scan codes, the system enables fast processing automatically.

Loading processing graphics files and generating processing programs.

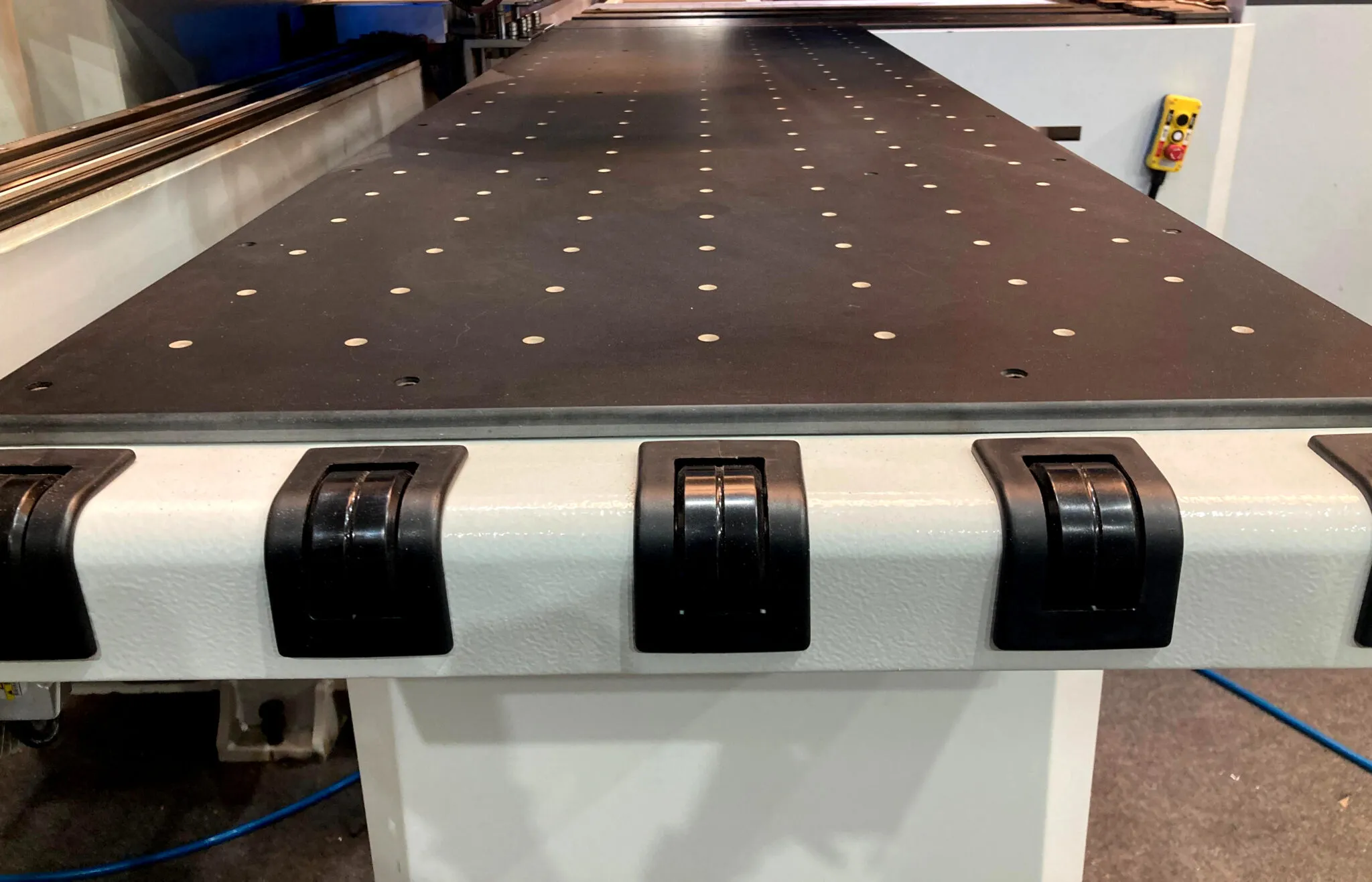

AIR FLOTATION TABLE

- A robust and durable table facilitates the automatic feeding of

panels for front loading. - It facilitated the easy movement of the panel through automatic lifting.

- Process the material without any scratches and perform seamless tasks.

- Capable of efficiently handling large and lengthy panels due to its

significant strength. - Fitted with a roller for effortless lifting of various types of panels.

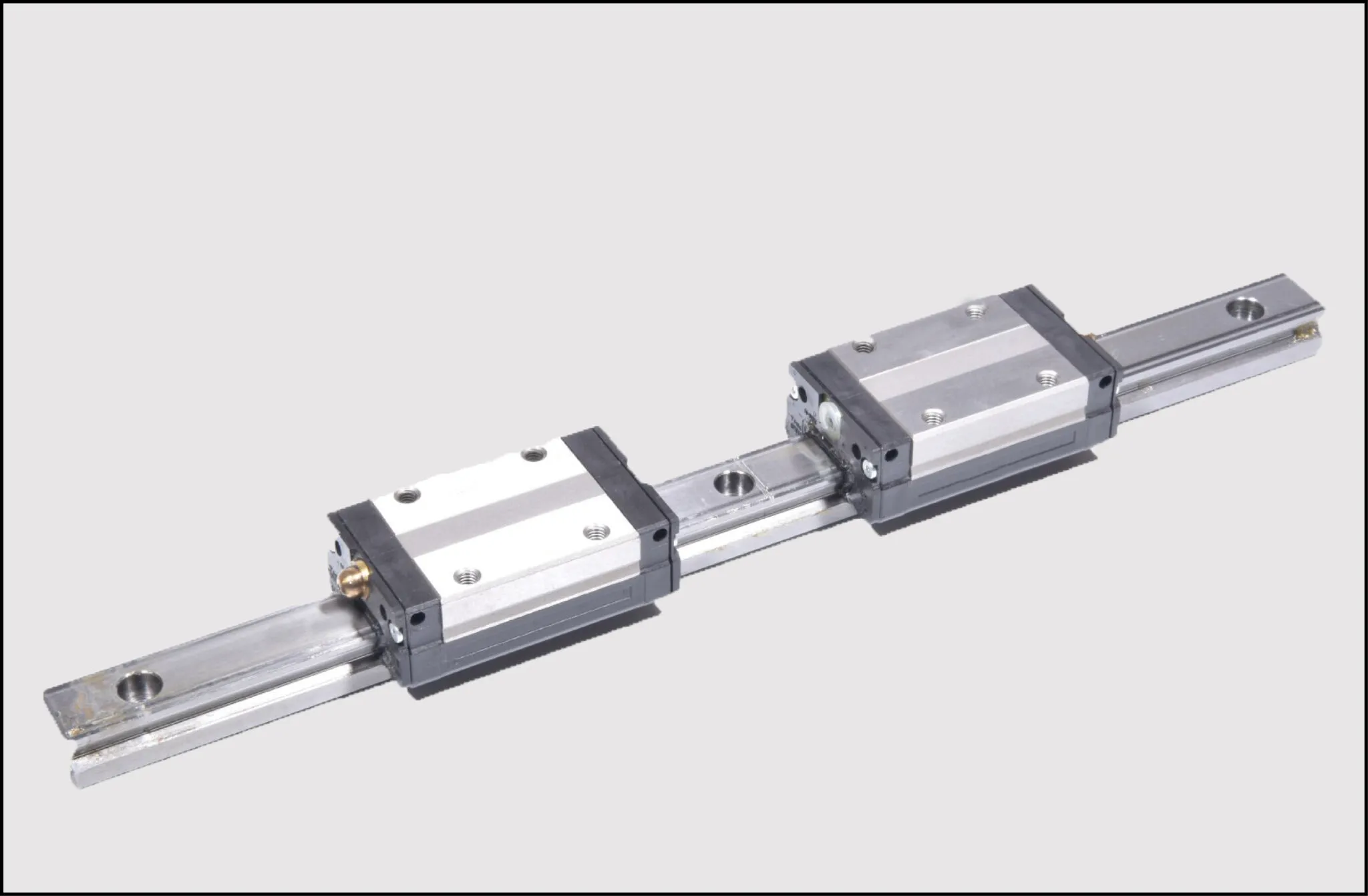

PRECISION LINEAR RAIL GUIDE

- Crafted to be resistant to dust and free from blockages

- The rail has been extended to accommodate extensive usage.

OPTICAL FIBER SENSOR

- It’s used for precise detection and placement of panels.

- The sensor is capable of detecting the dimensions of the panel.

- It ensures that the panel and the drill bag remain properly aligned.

- Equipped with a function that effectively prevents accidents.

BARCODE SCANNER

- Equipped with a barcode scanner for automatic calling of particular

program for particular panel - Will reduce the error while operating with quantity production

- Can be integrated into any software.

CNC Six Sided Drilling Machine U-612K for Sale

Application

Six-sided drilling, double-sided Grooving, milling processing

new upgrade: intelligent optimization of processing path

Salient Features

- Precise outer profiling of all four workpiece edges allows the complete formatting of the panels.

- The result are perfect formatted workpieces with finished, joined, and profiled edges

- Vertix is implemented for mass production with accuracy.

- Easy on material and time-saving for boring operations with an affordable price.

- Unique flexibility and performance.

- This machine is used in furniture industries for producing everything from drawers to body parts, furniture fronts, and rear walls; in short, complete machining of all your products.

- Short cycling times and extreme precision.

- Heavy-duty structure for maximum machining quality.

- Use the capacity of a full-fledged CNC machining center that takes minimum floor space.

- User-friendly & high productivity.

Technical Specifications

| TECHNICAL SPECIFICATION | |

|---|---|

| MODEL | U - 612 K |

| Workpiece length | 80-3050 mm |

| Workpiece width | 30 - 1200 mm |

| Workpiece thickness | 10-60 mm |

| X-axis moving speed | 150 m/min |

| Y-axis moving speed | 100 m/min |

| Z-axis moving speed | 45 m/min |

| Upper drill unit: vertical drilling | 12 nos |

| Upper Drill unit: horizontal drilling | 8 nos |

| Bottom drill units | 9 nos |

| Drill group power | 2 x 2.2 kw |

| Milling spindle speed | 18000 r/min |

| Milling spindle power | 2 x 3.5 kw |

| Total power | 17 kw |

| Working pressure | 6 ~ 8 bars |

| Approx. machine weight | 3500 kg |

Note: Technical specifications may be changed without any prior notice. Product images are just for reference.

Explore Our Most Selling Machines

Edge Bander

Panel Saw

Hydraulic Coldpress

Multi Boring

Urex CNC Router

About CNC Six Sided Drilling Machine U-612K

The CNC Six-Sided Drilling Machine U 612K features an advancement

UMABOY’s CNC Six-Sided Drilling Machine is equipped with advanced features to deliver top-notch performance:

Double Gripper: Ensures secure and precise handling of panels, enhancing stability and accuracy during the drilling process.

Servo Motor: Provides high precision and reliability in drilling operations, allowing for consistent and efficient performance.

Air Flotation Table: Facilitates smooth movement and positioning of panels, reducing friction and improving handling.

Controller Display: Offers an intuitive interface for easy operation and real-time monitoring of the machine’s functions and settings.

Precision Linear Rail Guide: Ensures smooth and accurate movement of the drilling head, contributing to high-quality results.

Optical Fiber Sensor: Enhances the machine’s accuracy by providing precise measurement and detection of panel positioning.

These features collectively ensure that the CNC Six-Sided Drilling Machine delivers exceptional performance, precision, and efficiency in panel drilling operations.

CNC Six-Sided Drilling Machine Benefits:

Enhanced Precision: With advanced features like precision linear rail guides and optical fiber sensors, the machine provides highly accurate drilling on all six sides of a panel, ensuring consistent quality and reducing errors.

Increased Efficiency: The ability to perform multi-sided drilling in a single operation streamlines the production process, reducing setup time and increasing throughput.