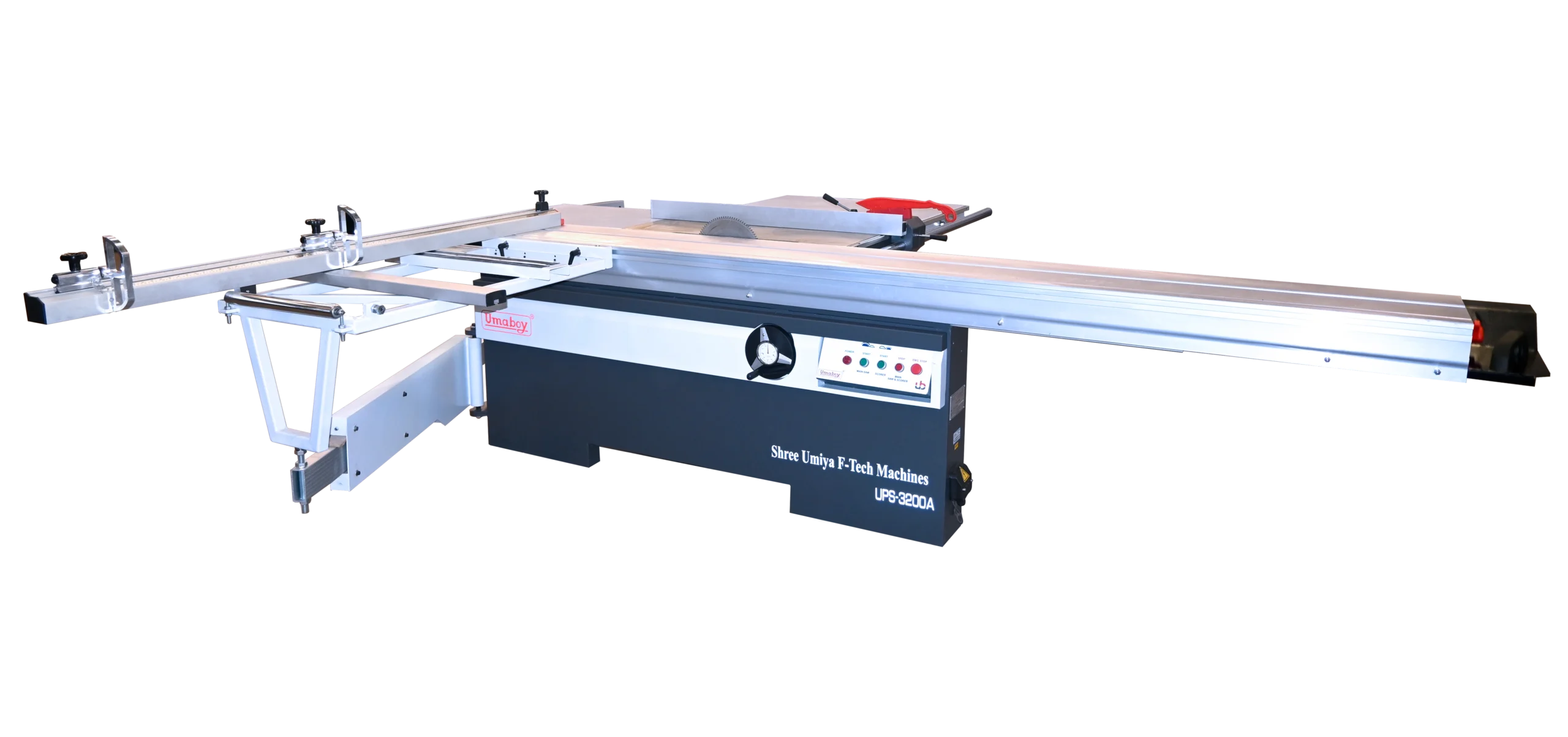

UPS 3200A

PANEL SAW WITH SLIDING TABLE

WATCH PRODUCT VIDEO

PRODUCT INFORMATION DESCRIBED BELOW ↓

HIGH PERFORMANCE CUTTING SOLUTION

INDUSTRIAL HEAVY DUTY SOLUTION FOR FURNITURE FACTORY

UMABOY specifically built this PANEL SAW machine to conduct woodcutting with precision and attention to quality. This may work well for cutting solid wood. MDF board, laminated board, plywood, and particle board.

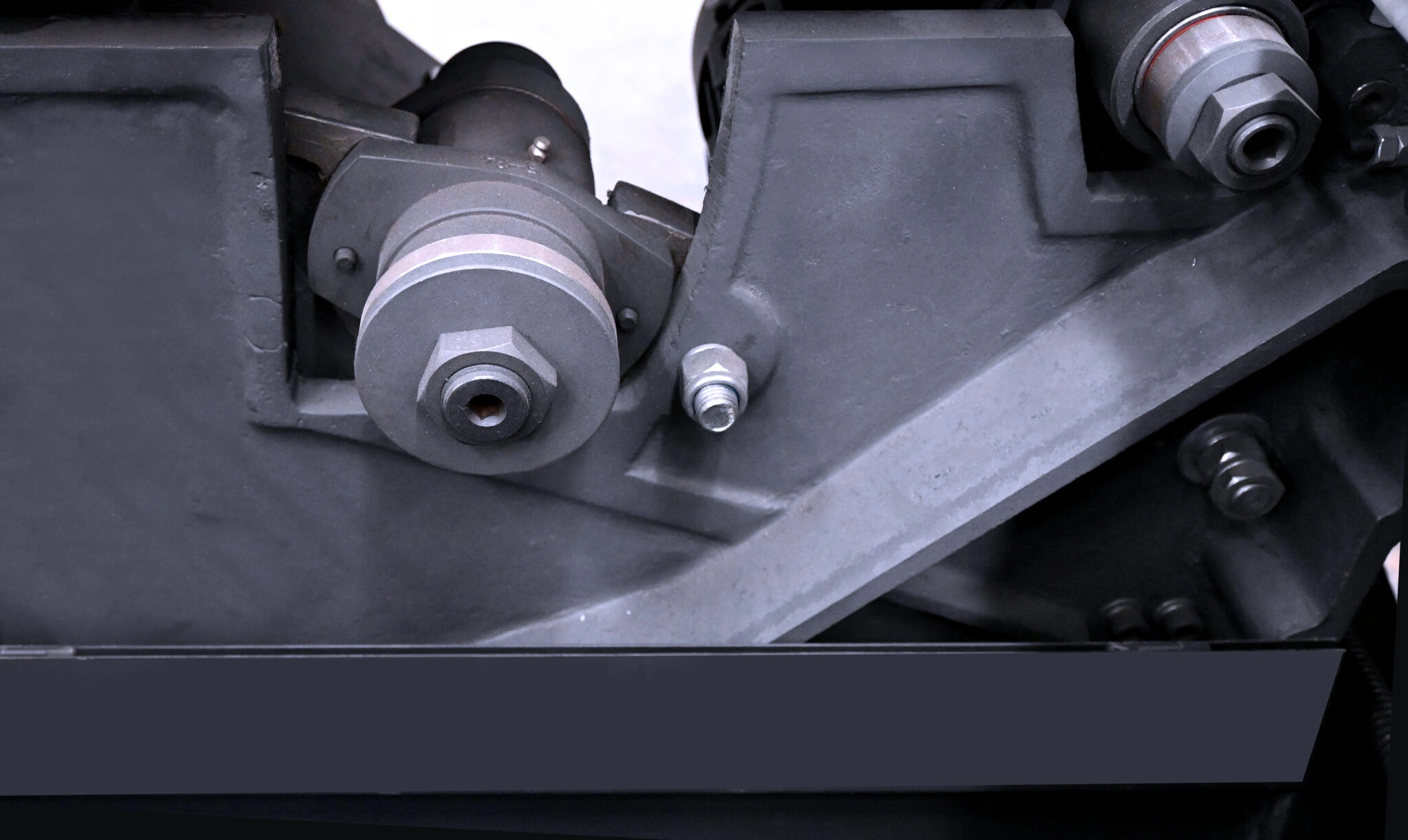

SAW UNIT

- For easy operation, smooth running with precise measurement cutting

- Machining of the head is done by VMC with 5 microns of precision.

- The system leads to vibration- and noise-free operation.

- Perfectly balanced housing.

SLIDING TABLE

- Extremely smooth running and multi-chamber system with linear steel bar bearing for high life.

- A double-layer aluminum structure gives better strength.

- In-built brush system cleans sliding road automatically.

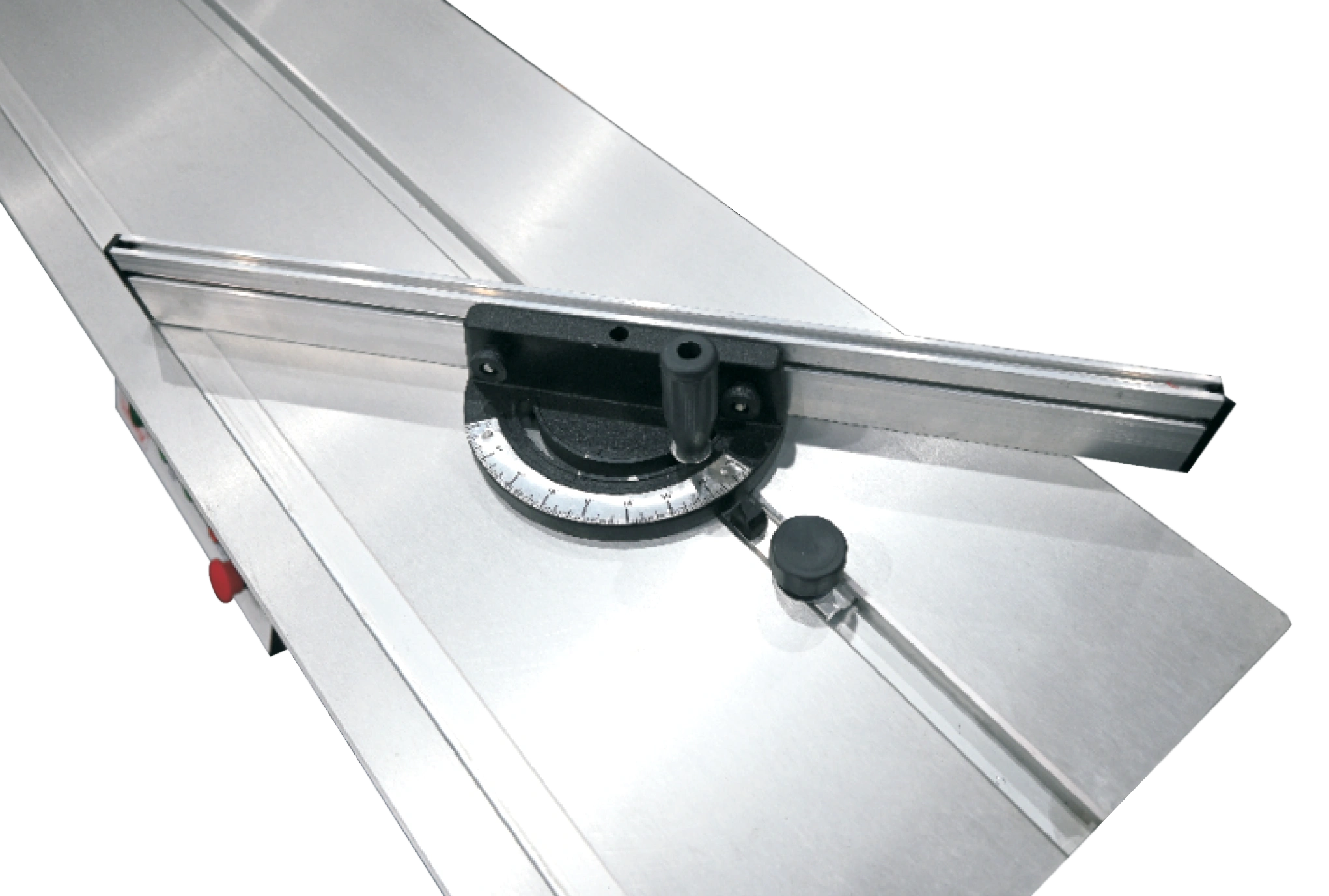

ANGLE FENCE

- Accurate angle adjustments, efficient operation, and calibration are all made possible by the precise angle meter.

- Helping to cut any type of custom size angle.

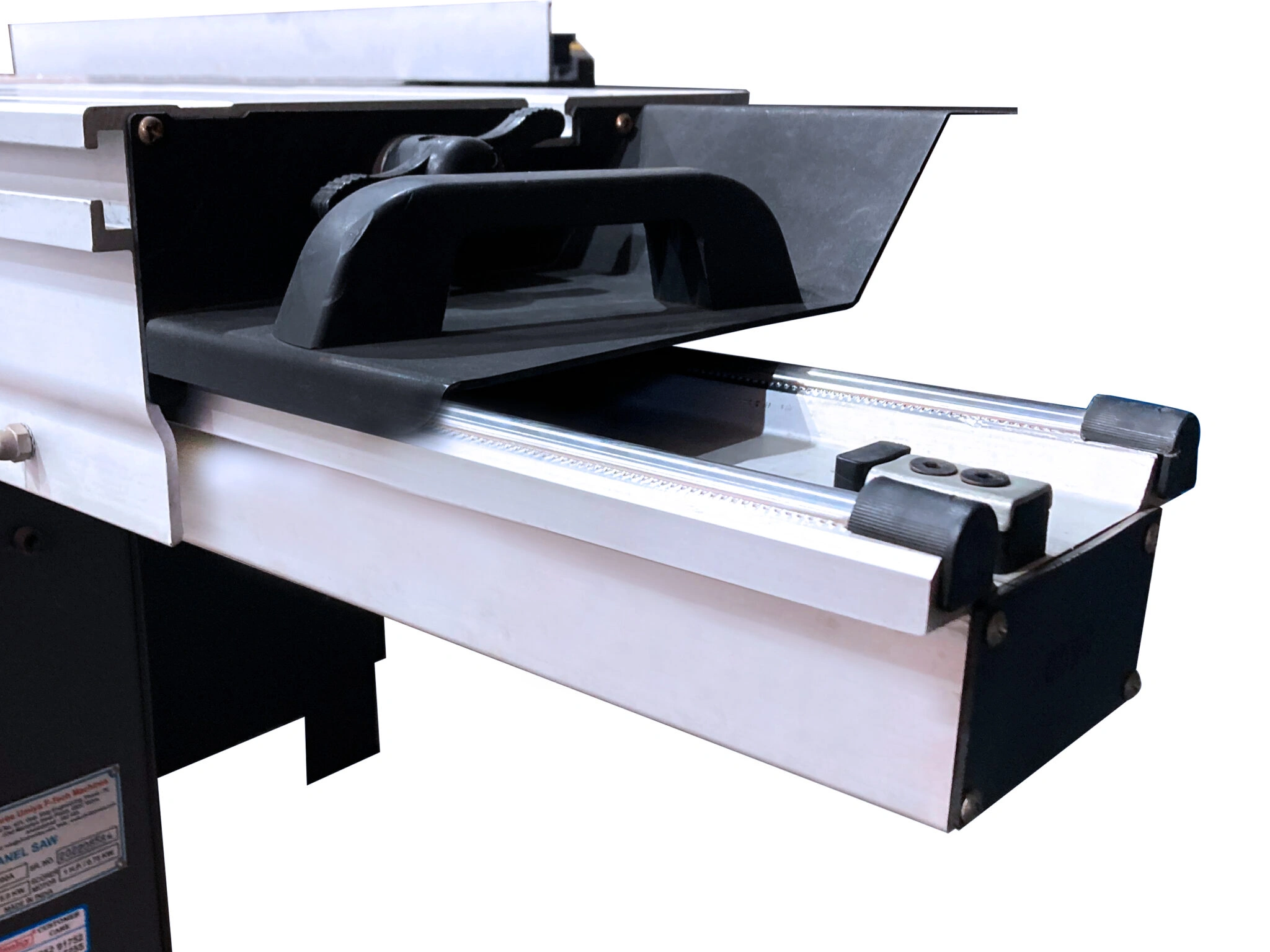

THE RIP FENSE

- For easy operation, smooth running with precise measurement cutting.

- Manual rip fence adjustment with cutting capacity up to 1220 mm.

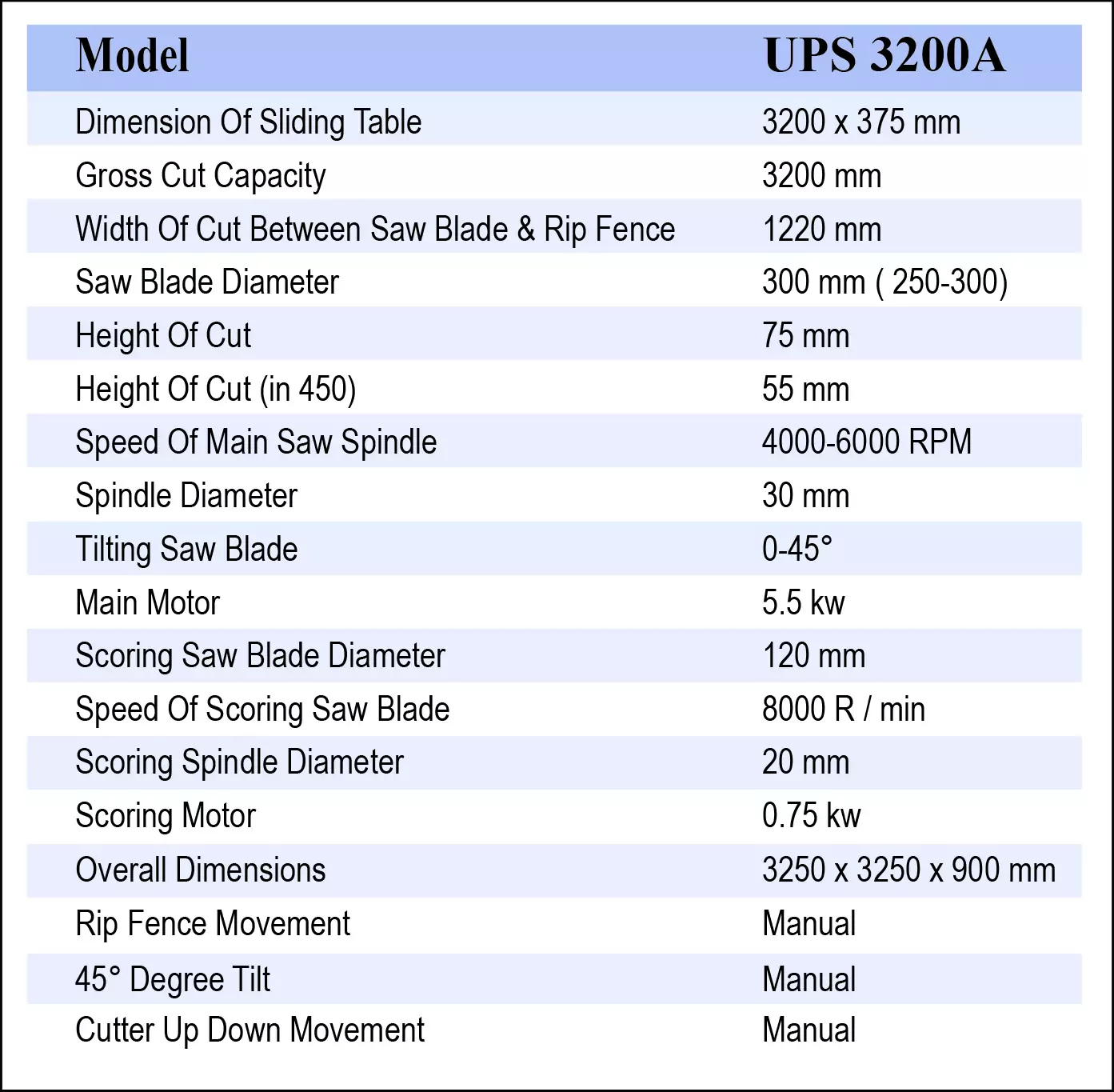

TECHNICAL SPECIFICATION

Panel Saw UPS 3200A

This panel saw machine is specifically built to conduct panel cutting with precision and attention to quality.

Technical Specifications

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Explore Our Most Selling Machines

Edge Bander

Panel Saw

Hydraulic Coldpress

Multi Boring

Urex CNC Router

About Panel Saw Machine 3200A

UMABOY specifically built this machine to conduct woodcutting with precision and attention to quality. This may work well for cutting solid wood.

MDF board, laminated board, plywood, and particle board. Aluminum alloy that has been utilized in a sliding guide panel with first-rate power for heavy and hard work. These machines include a sliding desk of high-power material, making it not likely to bend easily. The UMABOY Panel Saw 3200A is specifically engineered for precision woodcutting. The machine features a high-strength aluminum alloy sliding guide panel, providing exceptional durability and power for heavy-duty applications. Additionally, the sliding desk is constructed from a heavy material.

Application of the Panel Saw 3200A machine

- Precision Cutting: The Panel Saw 3200A, equipped with detailed manual measurement guides, ensures highly accurate cuts with minimal tolerance. This precision allows for exceptionally accurate wood cutting, making it ideal for tasks that require meticulous attention to detail. Whether you’re working on a complex project or simply need reliable performance, the 3200A’s accuracy and consistency help achieve professional-quality results.

- Adjustable Fence Systems: The adjustable fence on the Panel Saw 3200A facilitates quick and precise adjustments for cutting various sizes and angles. This feature enhances flexibility and efficiency, allowing you to easily adapt the saw to different cutting requirements while maintaining accuracy. Whether you need to make straight cuts or angled ones, the adjustable fence ensures that you achieve the desired results with minimal effort.

- High-Power Motors: The UMABOY Panel Saw 3200 A is equipped with high-RPM motors that deliver the power needed to cut through thick and dense materials efficiently. This robust motor capability ensures that the saw handles demanding tasks with ease, providing smooth and precise cuts even in tougher materials. Whether you’re working with hardwoods or other challenging substances, the high-RPM motors enhance the saw’s performance and reliability. making it indispensable for large-scale woodworking and manufacturing operations.

- Safety Features: The UMABOY Panel Saw 3200 A is designed with enhanced safety mechanisms, including blade guards, emergency stop buttons, and anti-kickback devices. These features work together to provide comprehensive protection for operators. The blade guards shield users from accidental contact with the blade, the emergency stop buttons allow for immediate shutdown in case of an emergency, and the anti-kickback devices help prevent material from being forcefully thrown back towards the operator. Together, these safety measures help ensure a safer working environment and reduce the risk of accidents.