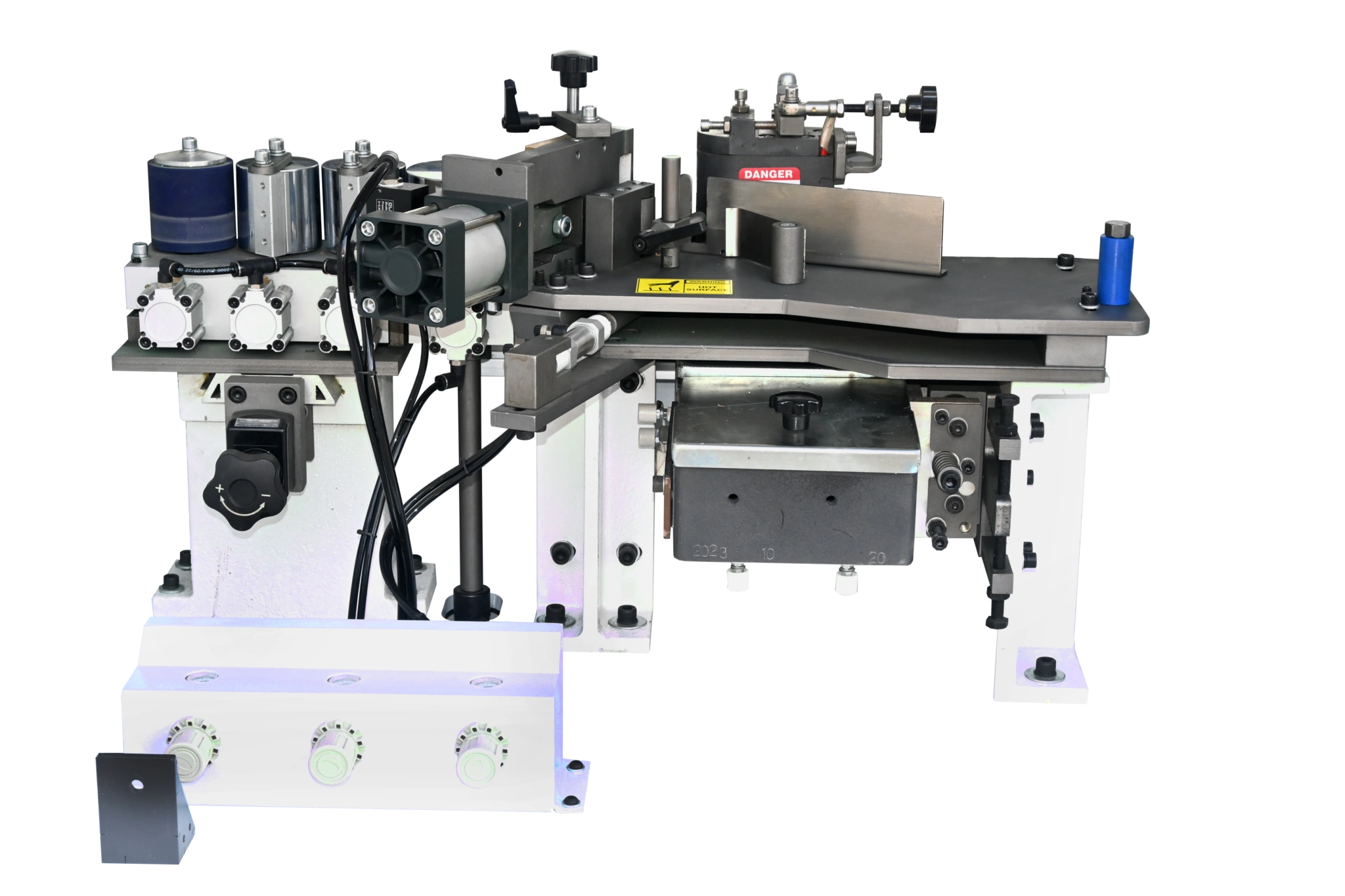

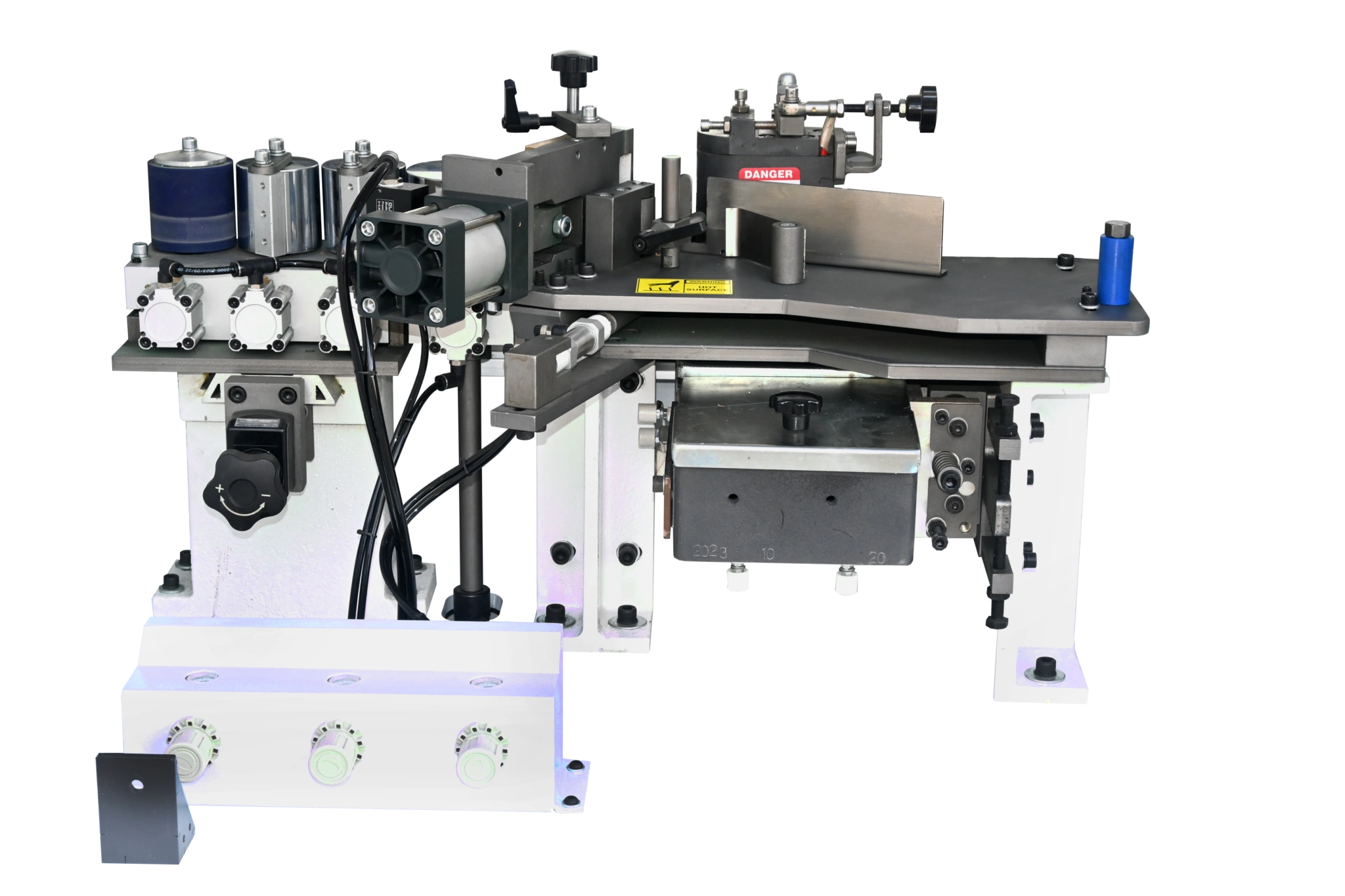

UEB 860 PC

AUTOMATIC EDGEBANDING MACHINE

WATCH PRODUCT VIDEO

PRODUCT INFORMATION DESCRIBED BELOW ↓

SEAMLESS EDGEBANDING MACHINE

SMART SOLUTION FOR ENHANCE QUALITY

The machine can be performing with many different Edgebands such as PVC, ABS, veneer and acrylic On different types of boards such as plywood, chipboard, MDF/HDF..

PREMILLING UNIT

- An automatic length sensor switch is installed, which allows accurate determination of panel length and processing of the entire panel.

- corrects the panel’s surface using premium auto-set High RPM Spindle frequency motors ( revolves both counter-clockwise and clockwise to provide a precise, chip-free finish.

- Equipped with a 1.5 KW spindle motor-powered, 12000 RPM diamond cutter head.

- The maximum board thickness for premilling is 50 mm, and the maximum cutting depth is between 0.2 to 2 mm

- There is a partition and an air blower installed between the Premilling Unit and the Glue Unit. The air blower removes dust particles for a quality and smoother gluing process

- the priming procedure creates a consistent surface and chip-free edge for the panel.

GLUE UNIT

- Apply the hot melt glue on the panel, Pneumatic cutting of pvc edge banding as per the length of panel, gluing on entire surface of panel height.

- Teflon coated gluepot to prevent wastage of glue. It works wonders for clearing away burnt glue. Gluepot with a 2 kilogram capacity and a 1.5 kw plate heating.

- Having a nurling roller with a 500 watt heating element ensures uniformity of glue on panel edge.

- The high quality superior wiper controlled the flow of glue.

- These features are specially designed to ensure a consistently precise finish and superior quality and to avoid any poor quality and Inconsistency of glue.

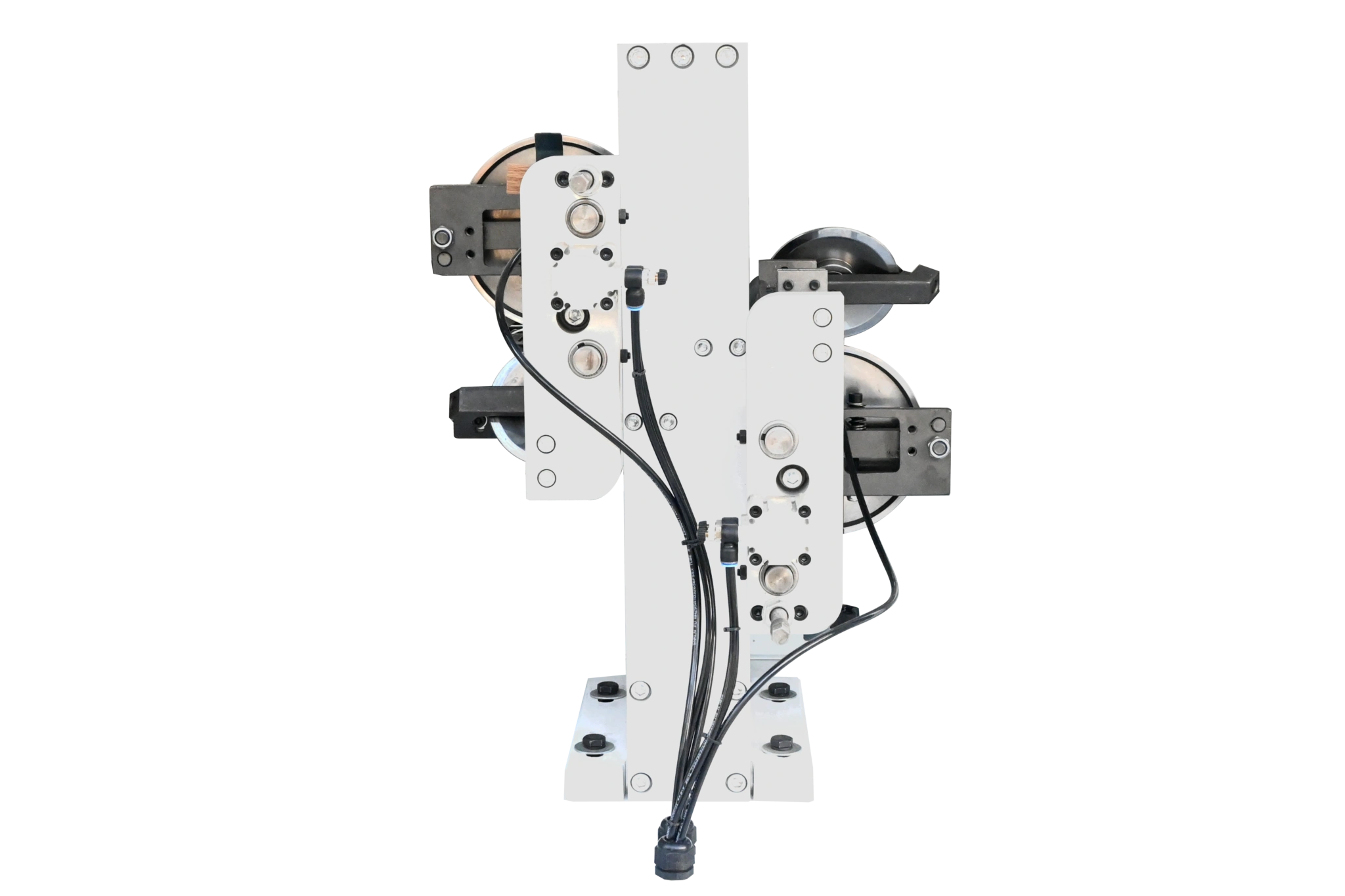

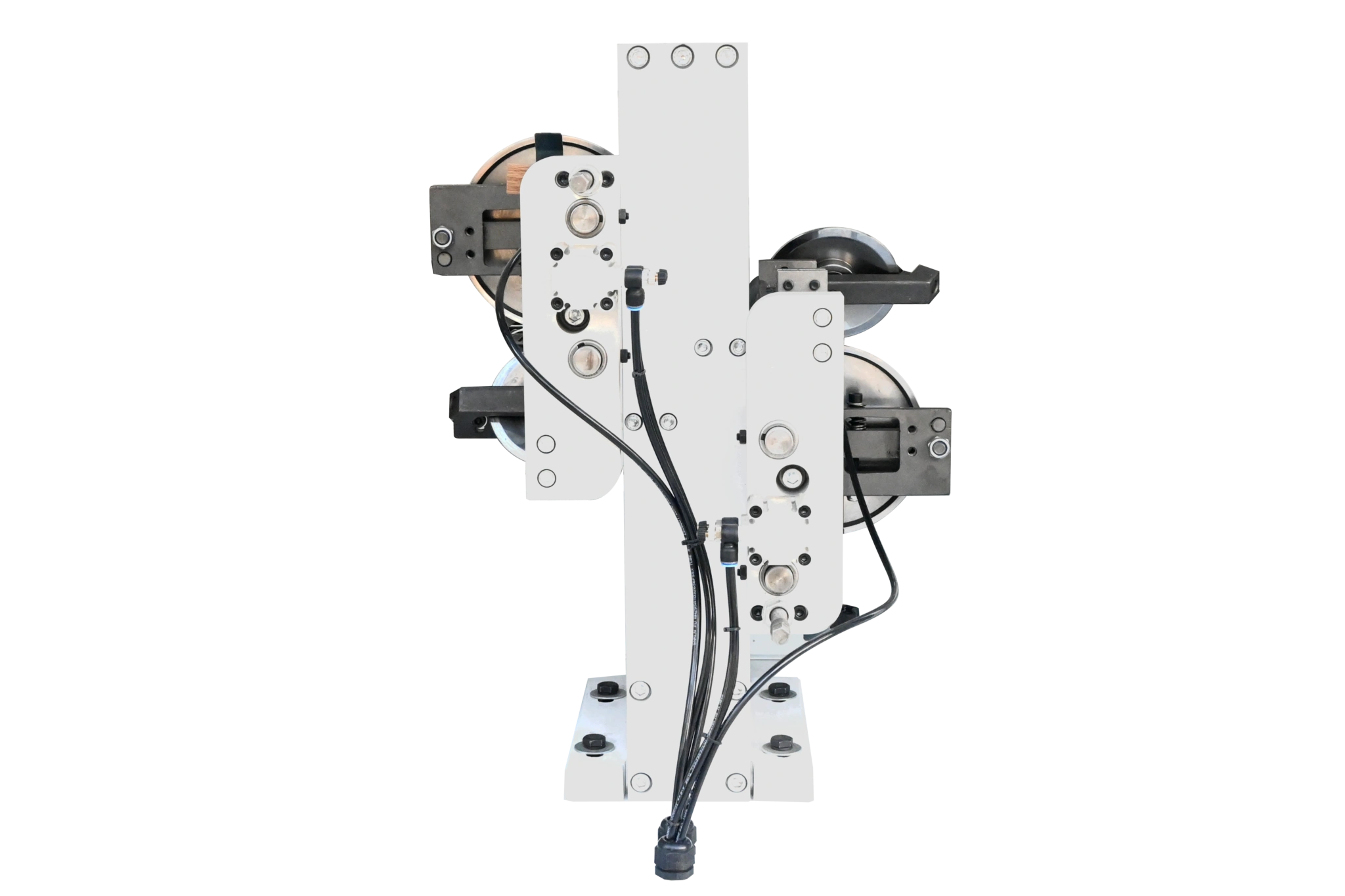

PRESSURE ROLLER GROUP

- A pressure roller group consists of 4 pressure roller diameters. The first pressure roller diameter is 150 mm and the remaining 3 pressure roller diameters are 100 mm

- Equipped with glue removig knife.

- All 4 pressure roller pneumatically operated. pressure can be adjustable by pnumatic pressure Nobe. function of pneumatic cylinder operated by PLC.

- The pressure rollers apply sufficient force to the panel to ensure that the glue adheres correctly and in the desired amount.

- It offers incredible results with a smooth finish and a long-lasting edge attached to the panel.

END CUTTING

- Unit used to cut excess pvc from both the end of panel. Equipped with high frequency motors with a power of 0.55 kW and 12,000 rpm and saw blades with a diameter of 150 mm.

- High reliability and precision as Installed large linear guides. 2 saw blades diam. 104 x 3.0 x 22 mm, T = 30.

- This process ensures a precise edge finish for a perfect finished look.

FINE TOP/BOTTOM TRIMMING

- Performs fine trimming of the top and bottom edges of the pvc edge.

- Comes with 2 highend frequency motors with suction hood and vertical Guide Plate.

- Motors manually tiltable between 2 working positions: Flat and radius trimming.

- Easy adjustments of trimming head as per thickness of pvc.

- High Frequency spindle motor – 0.55 kw x 2, 12000 RPM.

CORNER ROUNDING

- corner rounding unit for front and rear edges for perfect corner trimming.

- This unit works in different profile in prosessed post forming machine like half nose, full nose, and duck nose.

- having a capacity of 50 mm panel.

- High Frequency spindle motor – 0.55 kw x 2, 12000 RPM.

- Workpiece length min – 150 mm, edgebanding thickness upto 0.4 mm to 3mm.

- Thanks to it’s movement of circulating over the edge of panel with the help of linear guide ways and pneumatic cylinder gives the best result in the corner of panel.

PVC SCRAPPING

- PVC Scrapping does finishing work on edgebanding edges..

- Comes with standard profile of 2 mm.

- It provides better edge, consistency, precision and smoothness..

- Includes 2 R-profile blades with suction hood and front and vertical guide plate..

GLUE SCRAPPING

- The glue scraper helps remove excess adhesive from the joint surface of the panel and edgeband.

- Flat blade knife with copying plate and air cleaning function

- This process ensures that there is no glue on the panel or outside the application area.

- Work as a soft scrapper which gives fine finishing.

LIQUID SPRAYING

- Spraying anti adhesive liquid on panel before buffing unit give the clean finishing surface.

- Equipped with PLC controlled pneumatic flow.

- This process cleans the entire treated area to make it look rich and well-groomed..

BUFFING UNIT

- Edge banding machine buff wheels are used to polish and buff the edges of the top/bottom wood panels to create a smooth and glossy finish.

- which makes them sturdier and lasts a longer.

- Finishing the edge looks dimensional and attractive with this process.

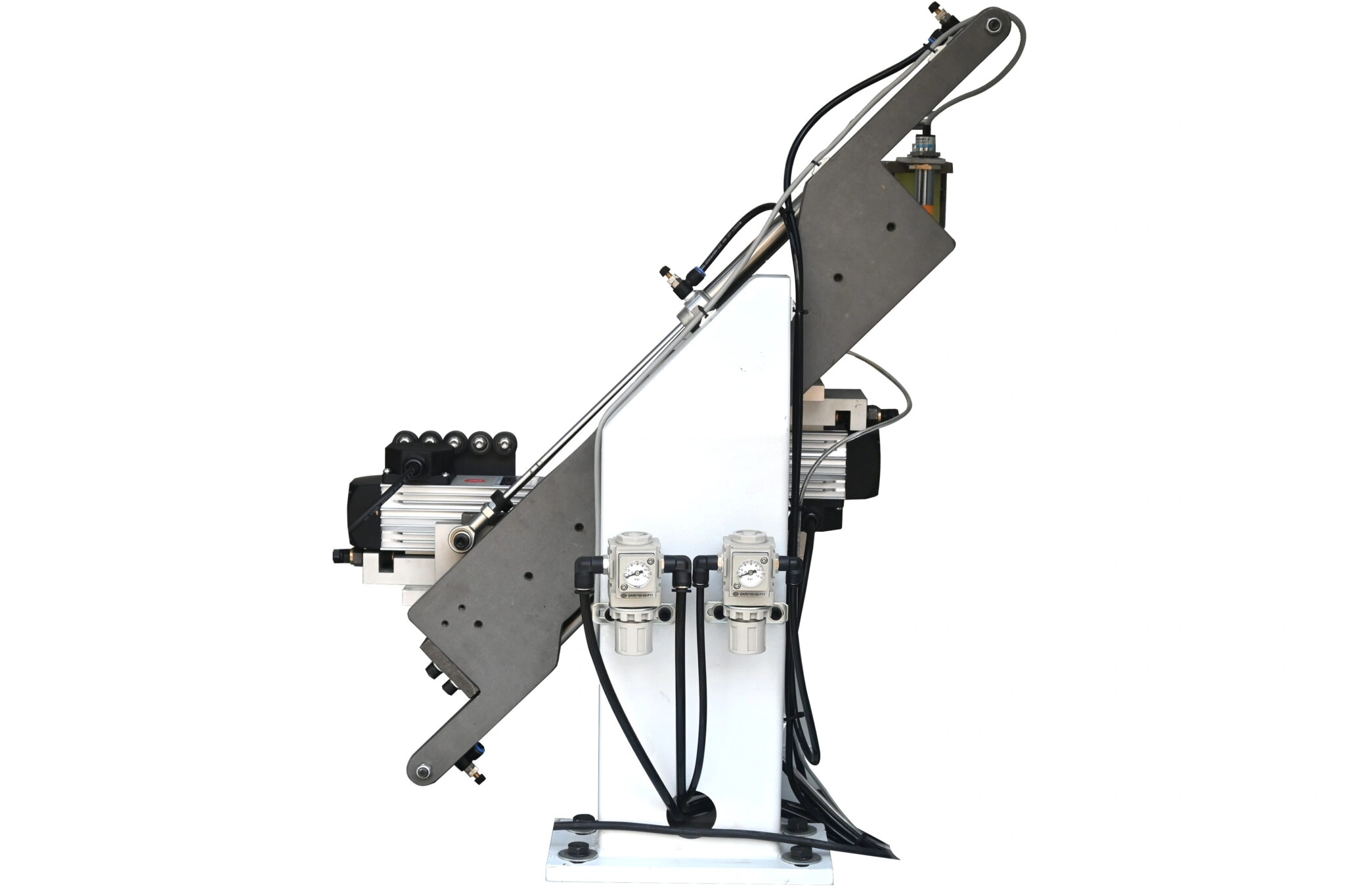

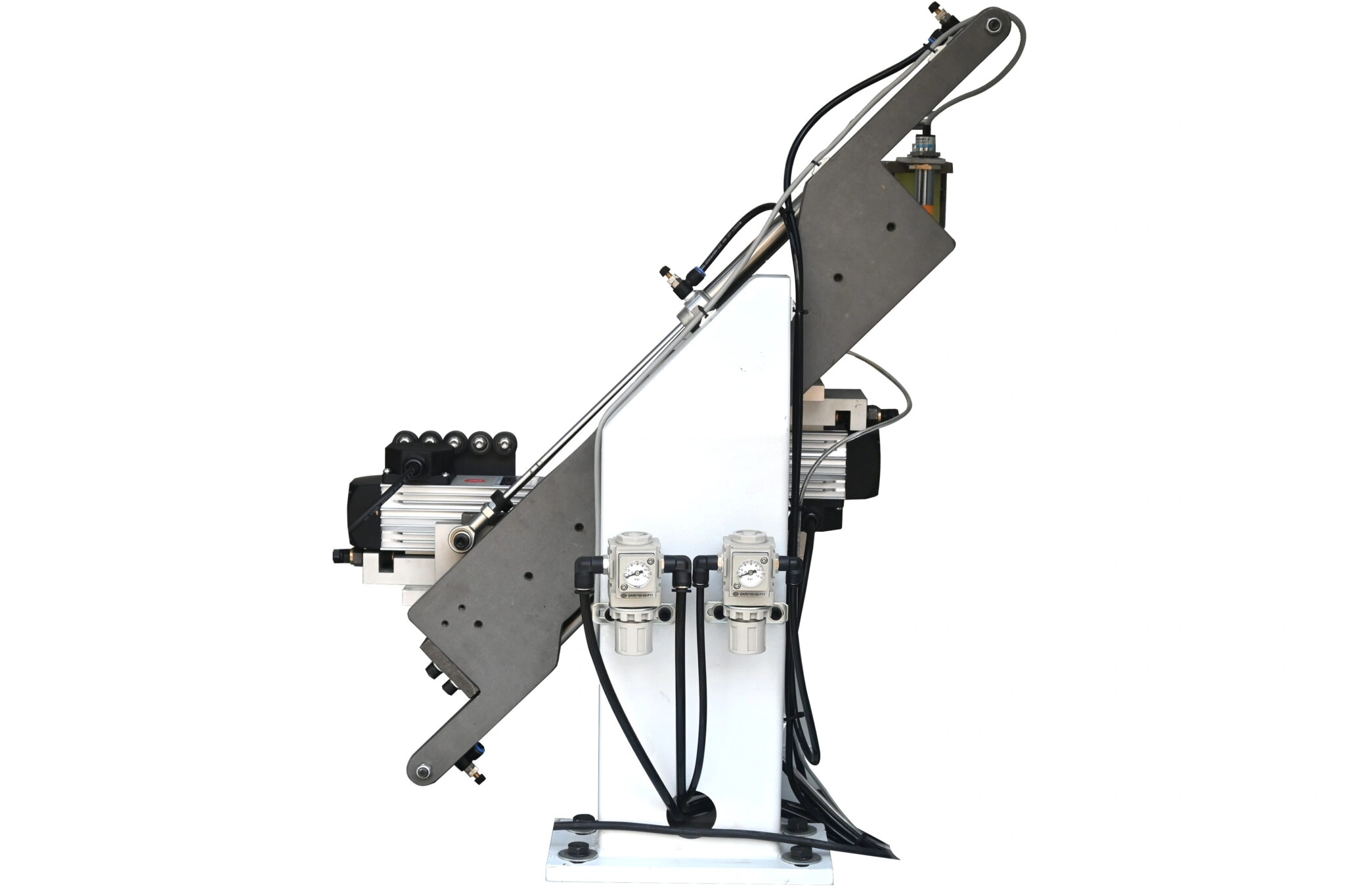

EXTRA ROLLER SUPPORT

- Additional roller supports for small workpiece.

- Proper gripping of panel throughout working.

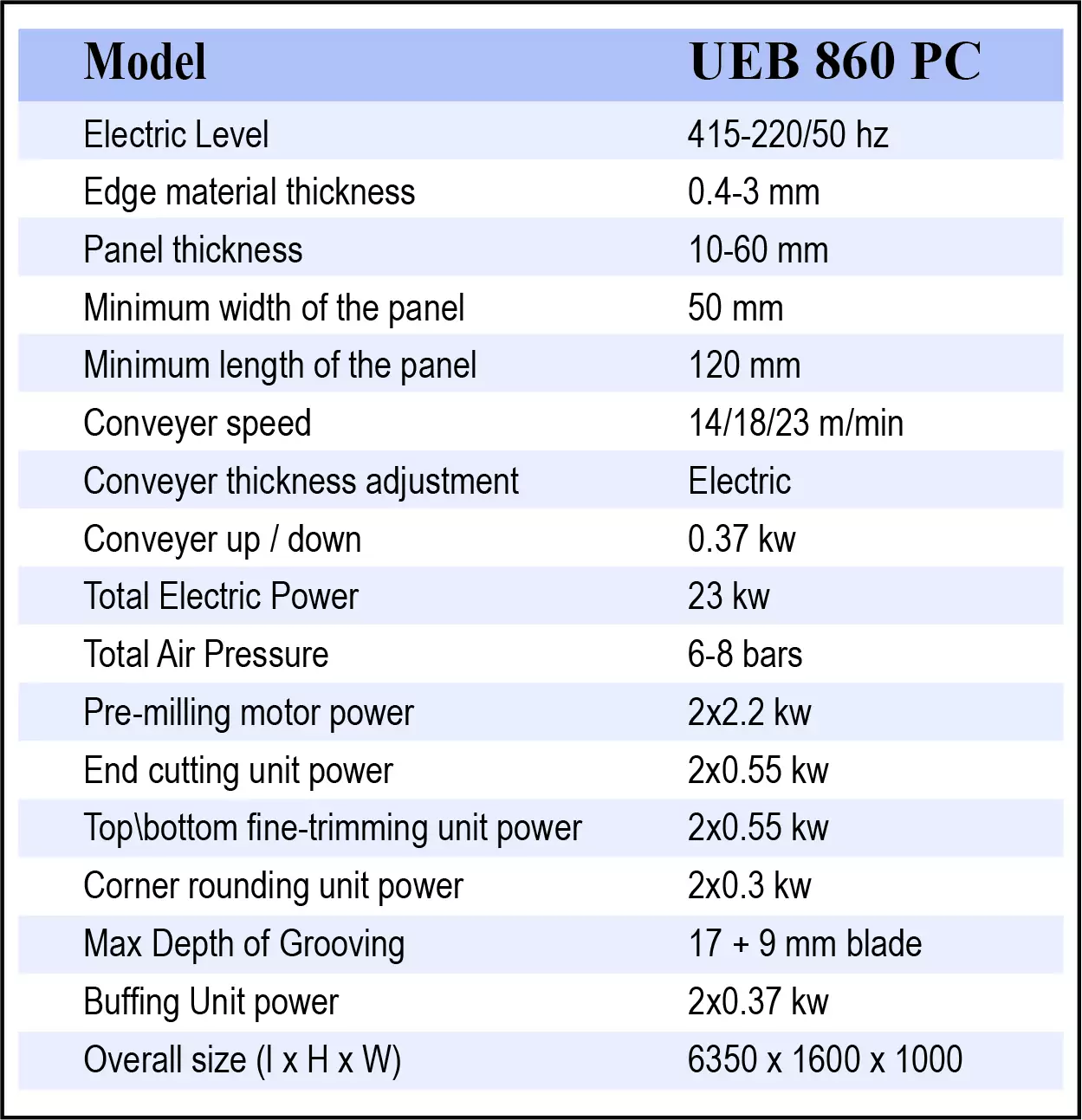

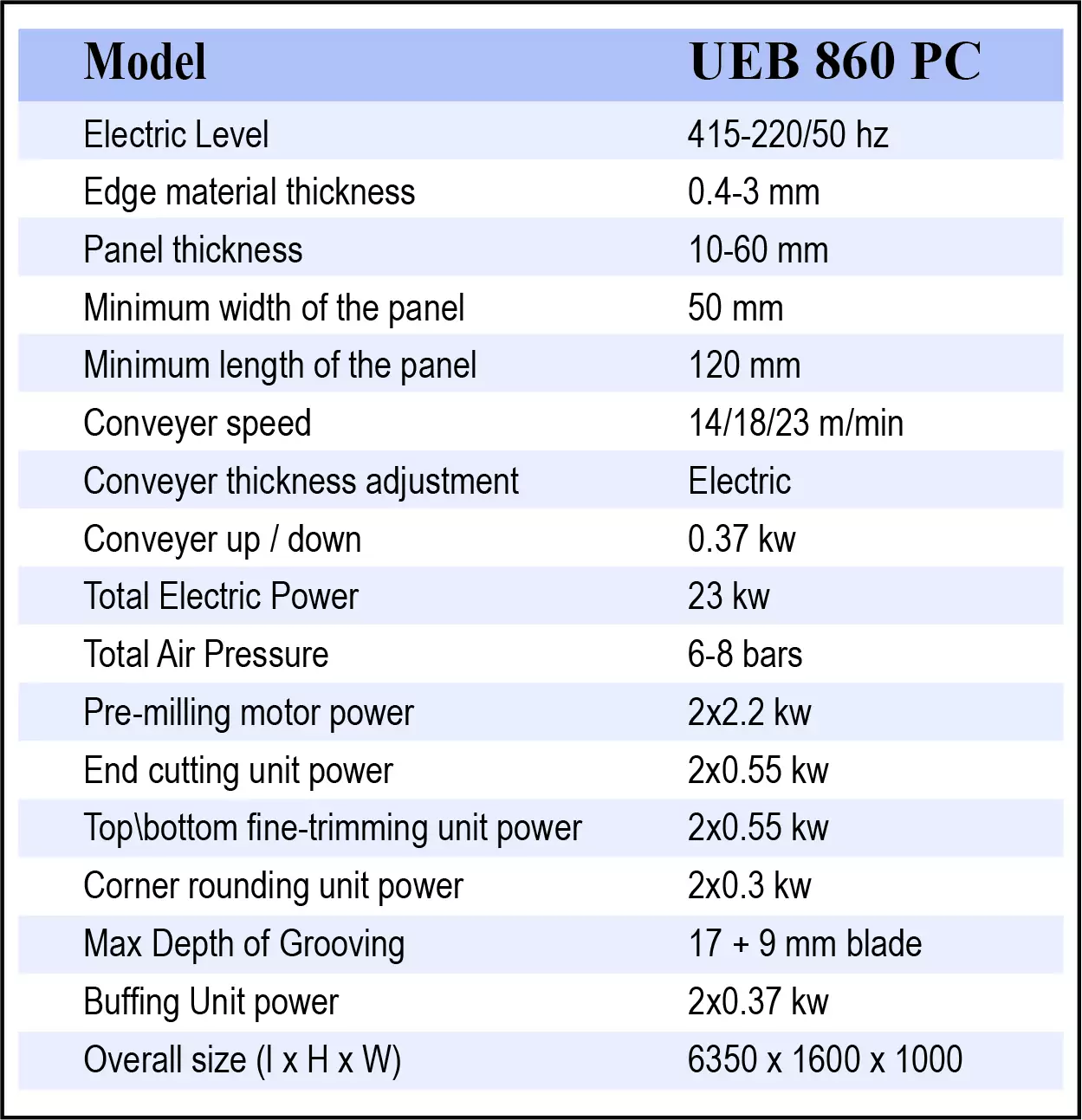

TECHNICAL SPECIFICATION

High Speed Auto Edge Bander UEB-860 PC

Salient Features

- High end machining performance: Optimized for large-scale production, the automatic edge bander UEB 860 PC provider offers high-speed processing, ensuring both user-friendly and trouble-free operation.

- Motorised up-down of conveyor belt: The edge bander UEB 860 PC manual includes a motorized conveyor belt with adjustable up-down control, enhancing the machine’s versatility and precision.

- Smart Touch PLC System: This system is integrated with encoder-controlled functionality, ensuring the UEB 860 PCGD Automatic Edge Bander Machine for sale operates with accurate and efficient performance.

- Equipped with Diamond pre milling Cutter: The machine is outfitted with a diamond pre-milling cutter, enhancing the overall performance of the automatic edge bander UEB 860 PC.

- Gluepot having a capacity of 2 KG of EVA glue: Featuring a 2 KG gluepot capacity for EVA glue, the automatic edge bander UEB 860 PC supplier in India guarantees a consistent and durable edge banding process.

- Safety air tank for constant supply of air to the machine: The machine is supported by a safety air tank, maintaining a steady air supply, essential for the robust performance of the automatic edge bander UEB 860 PC wholesaler.

Technical Specifications

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Explore Our Most Selling Machines

Edge Bander

Panel Saw

Hydraulic Coldpress

Multi Boring

Urex CNC Router

About Fully Automatic Edge Bander UEB-860 PC

The High Speed Auto Edge Bander UEB-860 PC is indeed a top-tier machine designed for high-volume production with a focus on premium quality. Here are some key features and aspects that make it suitable for such demanding requirements. This machine has equipped advance Pre-milling function, Glue unit, PVC and Glue Scrapping unit, Additional roller supports for small workpiece. To meet ultra precision quality.

The High Speed Auto Edge Bander UEB-860 PC feature and advancement

-

Features:

-

High-Speed Operation: As its name suggests, the UEB-860 PC is engineered for fast processing, which is crucial for large-scale production environments. It can handle high throughput without compromising on quality.

-

Precision and Quality: The machine is designed to ensure precise edge banding, which is essential for premium quality outputs. It often includes advanced technology for accurate application of edge bands and flawless finishes.

-

Versatility: It is typically versatile, accommodating various edge banding materials and thicknesses, which is valuable for diverse production needs and custom orders.

-

Automation: With advanced automation features, the UEB-860 PC can streamline operations, reduce manual labor, and minimize errors, enhancing overall efficiency.

-

Durability and Reliability: Premium segment machines like the UEB-860 PC are built with high-quality materials and components to ensure long-term reliability and minimal downtime, which is essential for continuous high-volume production.

-

Advanced Controls: It usually comes with sophisticated control systems and interfaces, allowing for precise adjustments and easy operation.

-

Integration Capabilities: The machine often integrates well with other production systems, which is beneficial for modern manufacturing setups that rely on interconnected processes.

Additional Roller Supports for Small Workpieces:- Purpose: These supports provide stability and guidance for smaller or lighter workpieces as they pass through the machine.

- Benefit: This minimizes the risk of misalignment and ensures consistent edge banding quality, even for smaller or delicate items.

Each of these features is integral to achieving the ultra-precision and high-quality finish required in premium production environments. By ensuring that every step of the edge banding process—from preparation to finishing—is handled with advanced technology and precision, the UEB-860 PC excels in meeting the demanding standards of high-end manufacturing.

-