U 1006-45°

MANUAL EDGEBANDING

WATCH PRODUCT VIDEO

PRODUCT INFORMATION DESCRIBED BELOW ↓

MANUAL EDGEBANDING MACHINE

SMART SOLUTION FOR ENHANCE QUALITY

The machine can be performing with many different Edgebands such as PVC, ABS, veneer and acrylic On different types of boards such as plywood, chipboard, MDF/HDF..

CONTROL PANEL

- Equipped with Length counter meter for processing pre define length of panel

makes easy to operate the machine - Result can’t be meet as in line with expectation.+

- Temprature controller is displaying of glue pot temprature

- glue roller speed can be adjust according to the users by ariable speed pot.

- Micro transfer / Foot transfer each alternative are to be had for running in this

machine. ( Call upon a users )

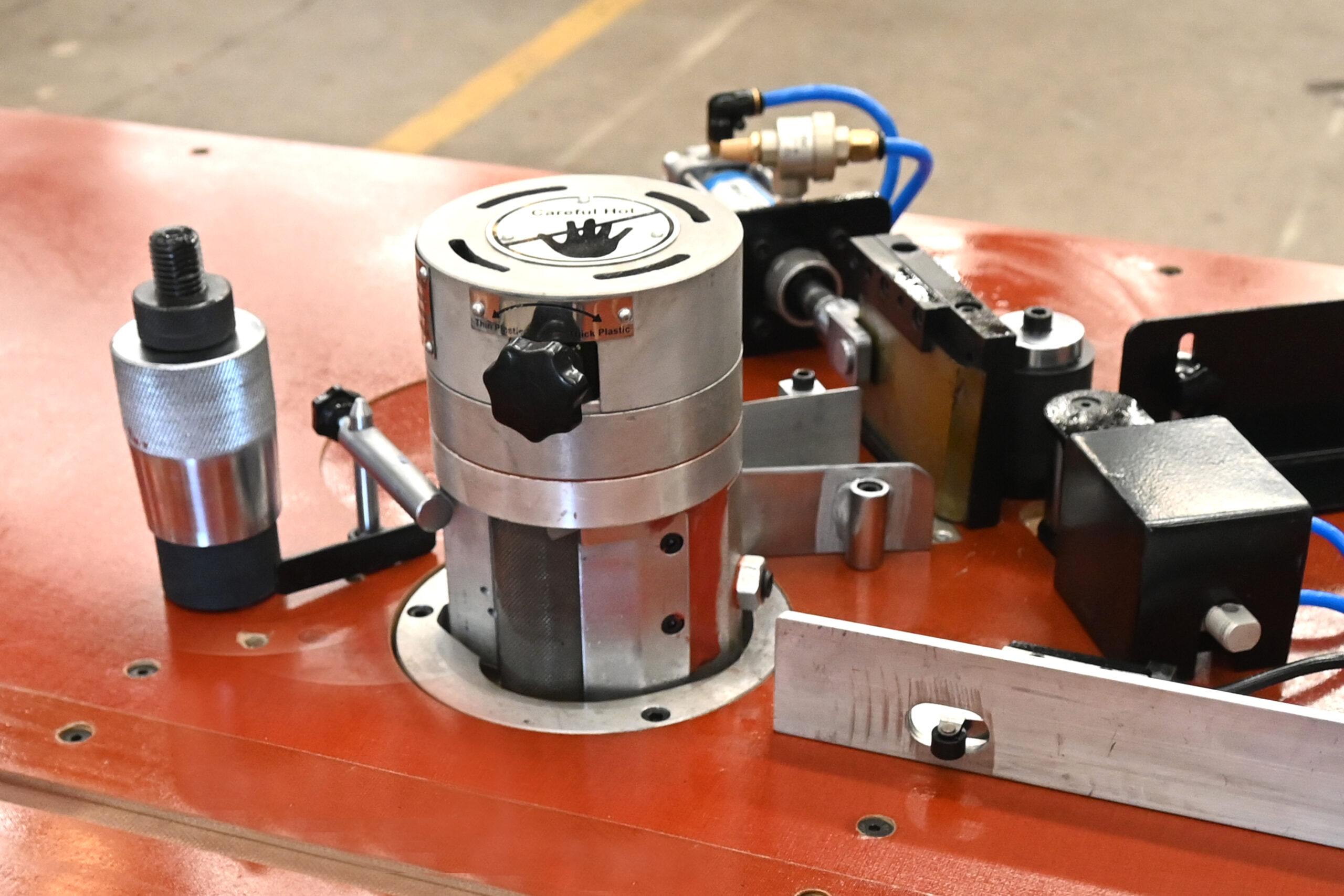

GLUE POT UNIT

- Equipped with 2.5 kg capacity of glue pot.

- For Increase and decrease Glue temprature at the glue roller is can be manage

through nobe. - Alluminium Diy casted glue pot offers an appropriate and uniform performance

in every day working.

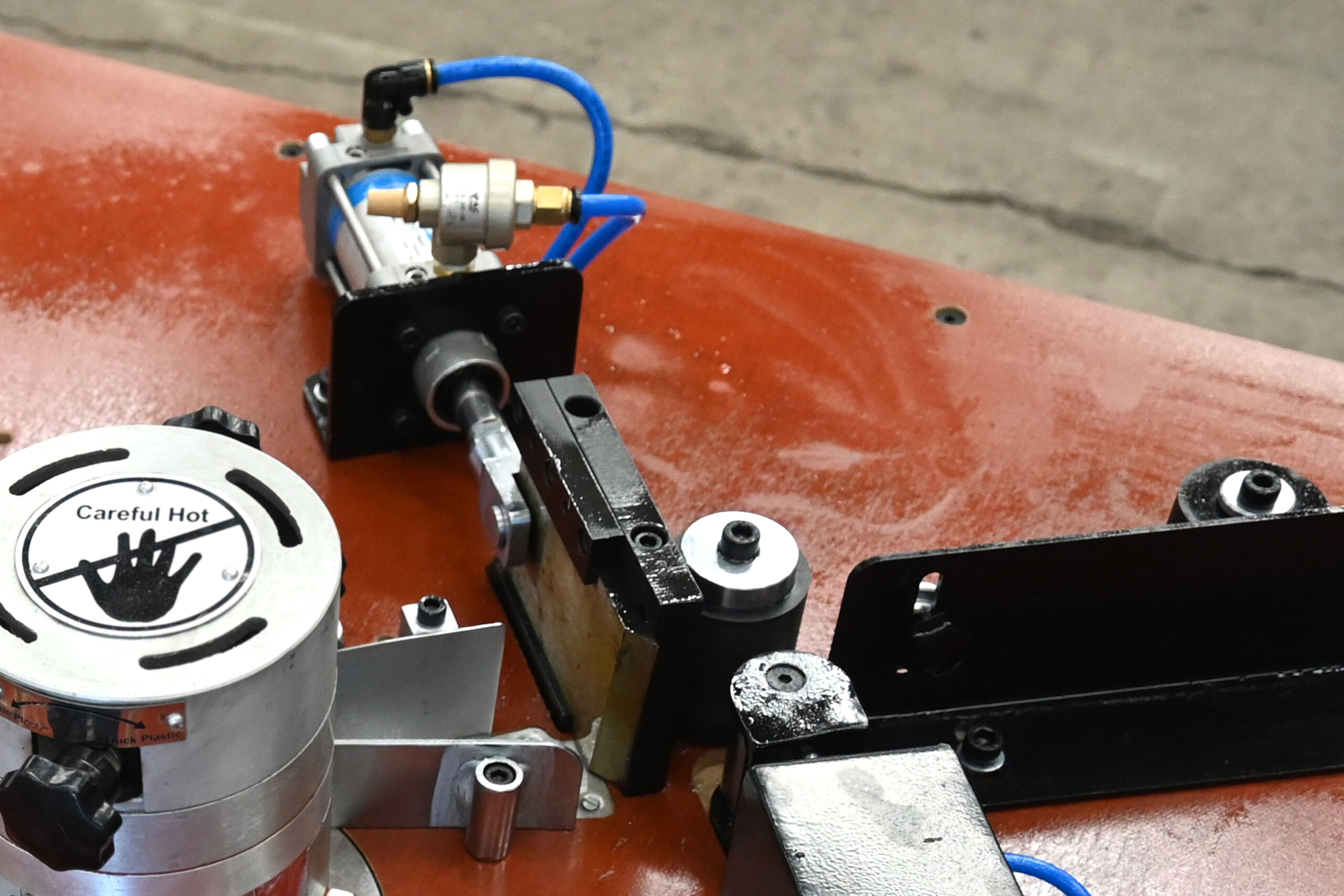

SCISOR UNIT

- Scissor Functionality is Pneumatically Equipped with SS sharp blade to cut

edge band smoothly. - It`s Connecterd to Foot Switch and Micro Switch ( Call upon user )

SWIVEL BAR

- Extended Swivel bar is to be had for wotking in a big length of panel.

- This extendness will assist to make heavy work via way of means of easily.

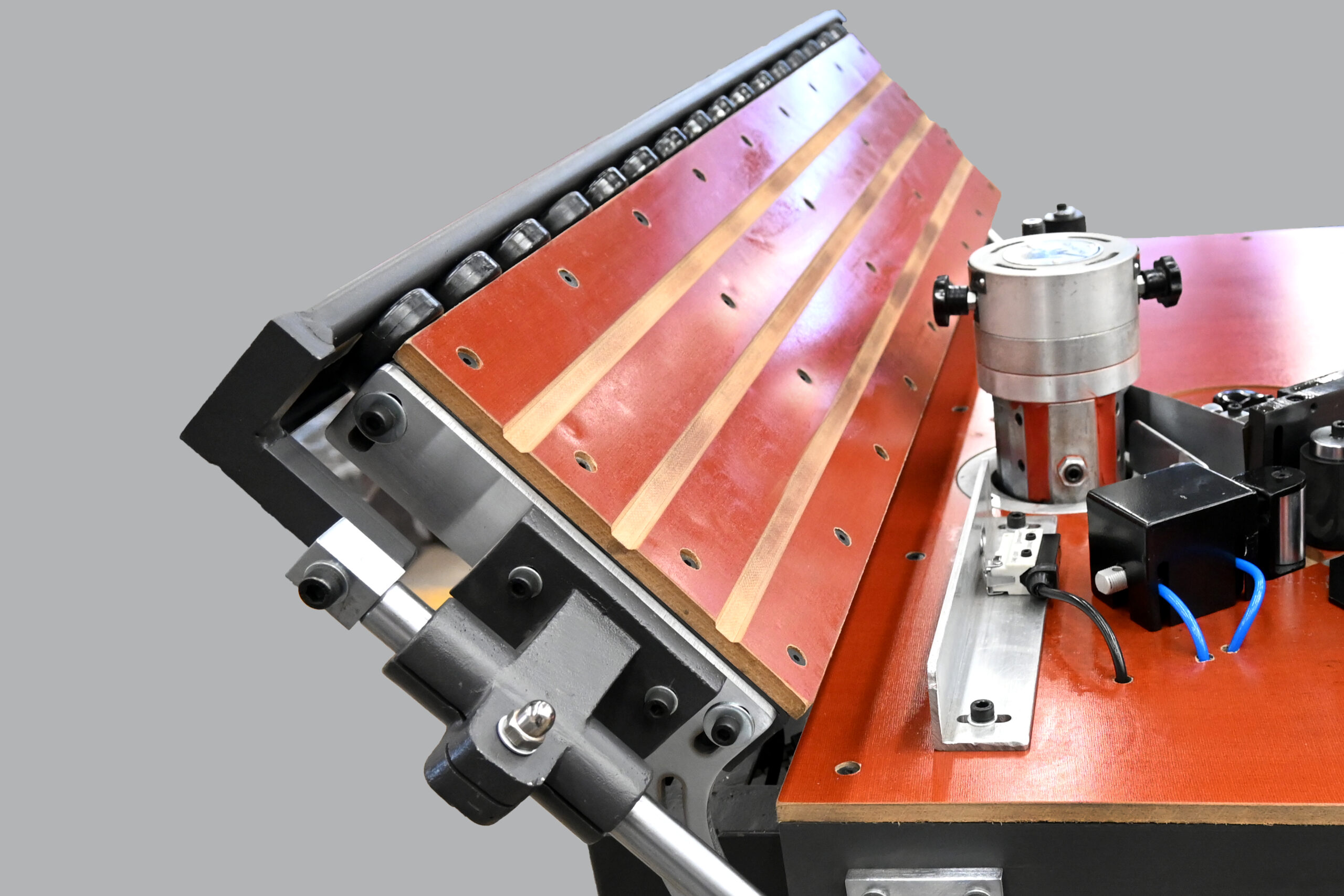

45° TILTING BAR

- Tilting desk is Equipped to apply edgeband on panel with 45° angle.

- It can be move till 45° and help to hold panel with perfect position and

get better stability. - The top workstation is equipped with Hylam sheet. which accomplished with

Heat resitant, shock proof, water proof

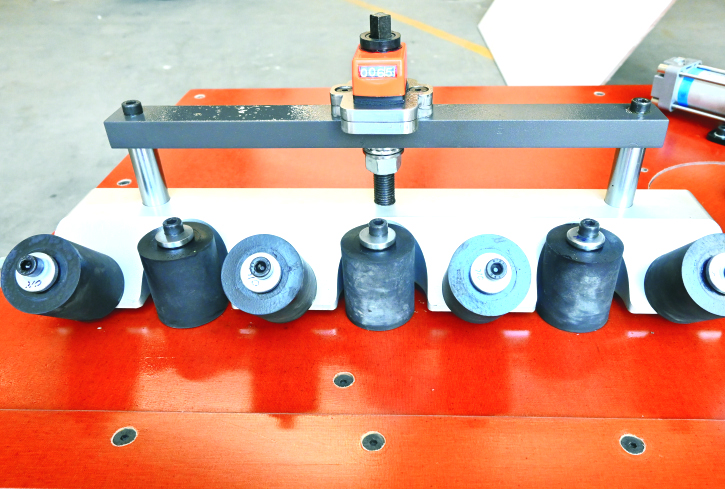

45° PVC EDGE BAND PRESSING UNIT

- Eqipped with 45° roller to pressing band for perfect stuck on panel

to log lastinf performance. - This rollers are one after the other symmetrically and with static position pressing edge band to straight and at 45° to make strong stuckness.

45° PVC V GROOVE UNIT

- 45° PVC V groove is fucntionning to make groove on edge band in order that

band can be stuck with panel in duck beak shape - High speed motor is equipped to V groove on band .

Manual Edge Banding UEB 1006-45°

Edge Banding without compromise is our motto.” And requirements as with edge banding. Umaboy offers a wide selection of different construction and performance machine models.

Salient Features

- Variable feed speed of edge banding.

- Swivel bar roller support for big width work piece.

- Aluminium glue pot with covering heat insulation material.

- Foot and micro cutting system for edge cutting.

- High speed motor equipped with ‘V’ groove tool.

- 45° & Straight pressing unit

Technical Specifications

| Model | UEB 1006-45° |

|---|---|

| Maximum thickness of work piece | 10 to 50 mm |

| Tape thickness | 0.4 to 2 mm |

| Glue pot capacity | 2 kgs. approx |

| Heating element | 3 kw |

| Tape cutting mechanism | Pneumatic |

| Control of tape cutting | Micro/Foot Switch |

| Working speed per minute | 0 to 10 mts (Variable) |

| Motor | 1 HP |

| Air pressure | 5 to 7 kg/cm2 |

| Tape coil dia | 525 mm |

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Let's talk !

Please fill out this form and relax.

Our expert executive team will reach out to you and

offer the most suitable advice according to your needs.

Please contact we would like to help you.

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Related to Products you've viewed

Explore Our Most Selling Machines

Edge Taping Machine

Edge Bander

Laminate Processing Machine

Hydraulic Coldpress

Panel Cutting Machine

Panel Saw

Multiple Drilling machine

Multi Boring

CARVING MACHINE