UBS 3200 AUTO

AUTOMATIC CNC BEAM SAW MACHINE

WATCH PRODUCT VIDEO

PRODUCT INFORMATION DESCRIBED BELOW ↓

HIGH PERFORMANCE MULTI CUTTING SOLUTION

SMART SOLUTION FOR ENHANCE QUALITY

This machine process the attributes of an excellent design, effortless functionality, and rapid manufacturing. It is particularly well-suited for precision cutting of straight and smooth wooden panels used in the production of office furniture and household furniture.

PROCESSING

- The components and machine frame undergo precision machining

using state-of-the-art CNC equipment for metalworking. - This streamlined process ensures high processing accuracy and

minimizes vibrations during operation.

QUALITY CONTROL

- The utilization of sophisticated measuring tools and a rigorous quality control system ensures that the machinery and components undergo thorough inspection and are certified to meet exceptionally high standards.

- Each machine comes with a Quality Certificate signed by a specialist in quality control.seamless task.

- Exceptional quality combined with cutting-edge technology can lead to a 40% boost in efficiency.

OPTIMIZING SOFTWARE

- The machine is equipped with professional optimization software

to ensure efficient handling and convenient operation. Additionally,

it is compatible with other globally recognized software for further

application. - The software is incredibly powerful and user-friendly, offering a

range of features such as comprehensive work process management

with detailed reports, simulation of cutting patterns, display of error

messages, printing of barcodes, and numerous other advantages.

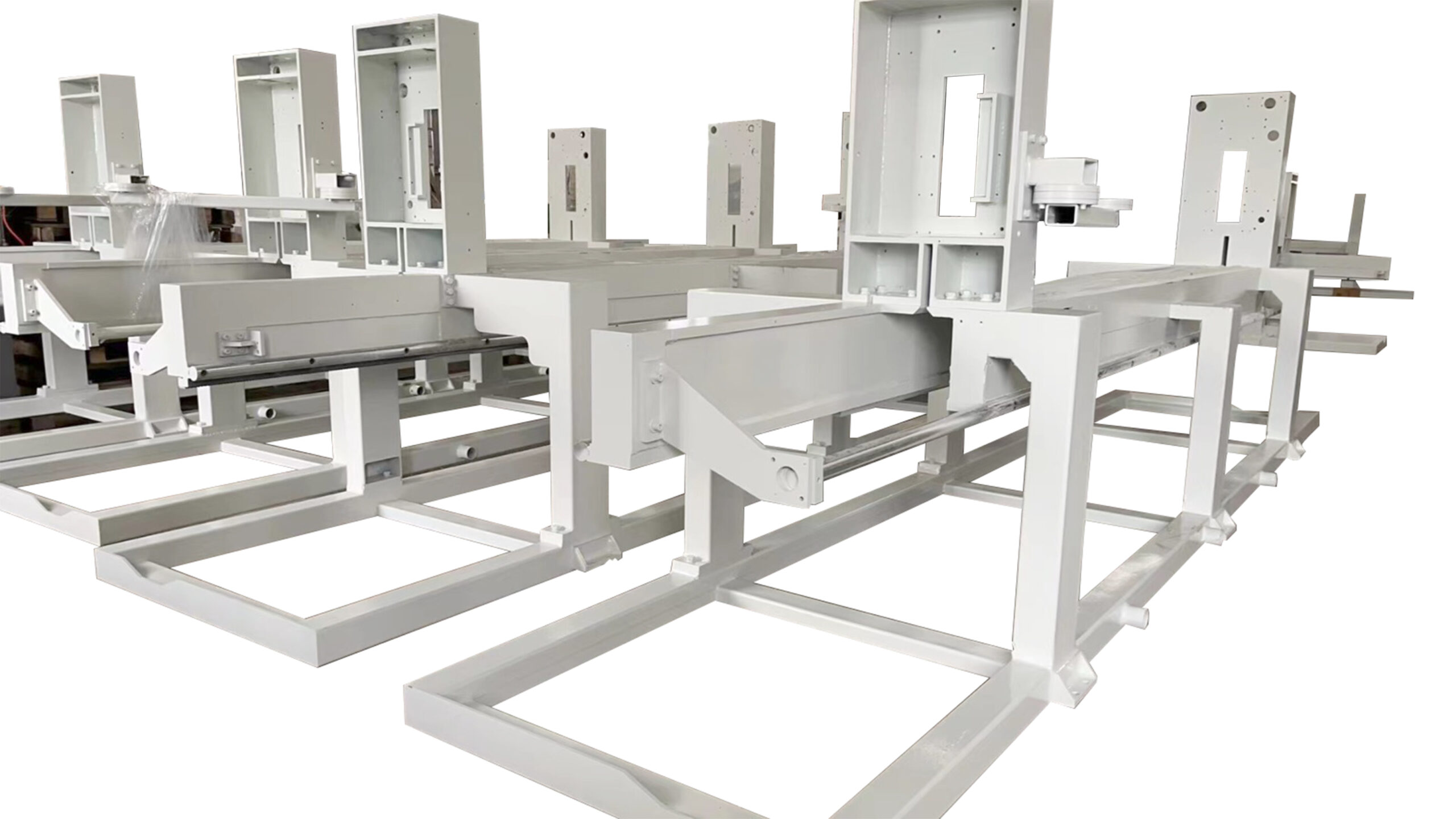

MACHINE BODY

- The steel plate possesses exceptional rigidity and durability, ensuring an extended lifespan and precise accuracy of up to ±0.03mm, thereby minimizing potential maintenance expenses.

- A polished surface reduces the risk of scratches on components.

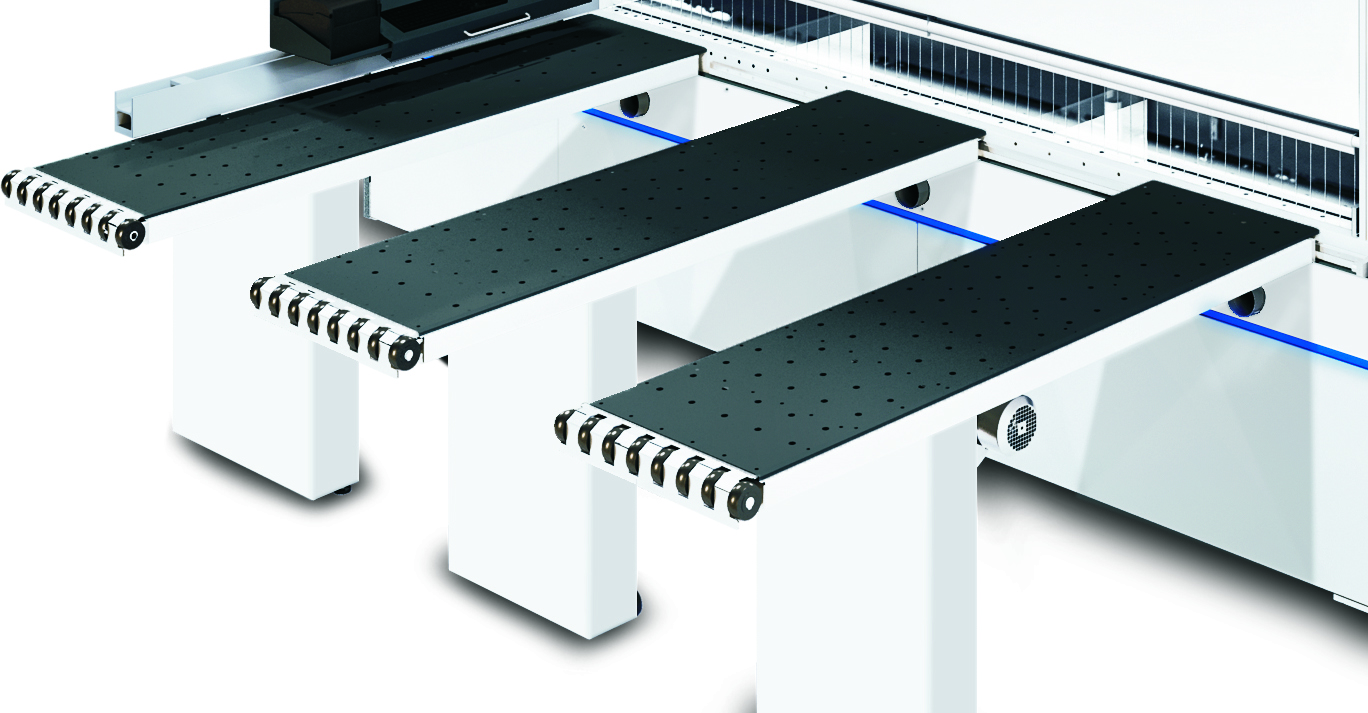

AIR FLOAT FEED TABLE

- The presence of steel balls on the table surface, along with a fan, guarantees smooth movement of panel stacks by providing constant air circulation.

- The black table plate is sturdy and resistant to wear, ensuring the optimal protection of the panel surface.

- Three pipes are linked to three float tables, and a air blower positioned beneath the table provides an ample supply of air. The flow rate is measured.

TECHNICAL SPECIFICATION

Manual Beam Saw UBS 3200 AUTO+

Maximum Production Output with Excellent Cutting of Multiple Panels

Saw Carriages

The saw carriage hold 400mm dia meter main blade and standard 180mm dia meter scoring blades with independent motor.

Protected by special dust scrapers.

Pneumatic clamping for ensuring both ends clamping.

Slient Features

After automatically testing sheet material and calling off the length of needed sheet is will rapidly return to await orders.

The saw is firm and high quality guide track & saw blade ensure the stable mechanical performance.

Can saw many layers of boards to improve efficiency

Advanced dust precipitating system can reduce environmental pollution.

Computer Controlled Beam Saw Machine

| Model | UBS 3200 AUTO+ |

|---|---|

| Saw cutting length | 3250 mm |

| Saw cutting thickness | 120 mm |

| Diameter of main saw blade | Ø 450 mm |

| Revolving speed of main saw blade | 3930 rpm |

| Diameter of scoring saw blade | Ø 180 mm |

| Diameter of scoring saw blade shaft | Ø 30 mm |

| Revolving speed of scoring saw blade | 6500 rpm |

| Advance speed of saw base (stepless) | 9-50 m/min |

| Back speed of saw base | 100 m/min |

| Drive motor of saw base | 1 KW |

| Drive motor of main saw blade | 15 KW |

| Automatic feeding motor | 1.5 KW |

| Automatic feeding speed | 50 m/min |

| Operating pressure | 5⁓8 Kg/cm |

| External dimensions(LxWxH) | 5830 X 6630 X 1810 mm |

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Let's talk !

Please fill out this form and relax.

Our expert executive team will reach out to you and

offer the most suitable advice according to your needs.

Please contact we would like to help you.

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Explore Our Most Selling Machines

Edge Bander

Hydraulic Coldpress

Panel Saw

Multi Boring