UBS 3200 AUTO

AUTOMATIC BEAM SAW

WATCH PRODUCT VIDEO

PRODUCT INFORMATION DESCRIBED BELOW ↓

HIGH PERFORMANCE MULTI CUTTING SOLUTION

SMART SOLUTION FOR ENHANCE QUALITY

This machine process the attributes of an excellent design, effortless functionality, and rapid manufacturing. It is particularly well-suited for precision cutting of straight and smooth wooden panels used in the production of office furniture and household furniture.

PROCESSING

- The components and machine frame undergo precision machining

using state-of-the-art CNC equipment for metalworking. - This streamlined process ensures high processing accuracy and

minimizes vibrations during operation.

QUALITY CONTROL

- The utilization of sophisticated measuring tools and a rigorous quality control system ensures that the machinery and components undergo thorough inspection and are certified to meet exceptionally high standards.

- Each machine comes with a Quality Certificate signed by a specialist in quality control.seamless task.

- Exceptional quality combined with cutting-edge technology can lead to a 40% boost in efficiency.

OPTIMIZING SOFTWARE

- The machine is equipped with professional optimization software

to ensure efficient handling and convenient operation. Additionally,

it is compatible with other globally recognized software for further

application. - The software is incredibly powerful and user-friendly, offering a

range of features such as comprehensive work process management

with detailed reports, simulation of cutting patterns, display of error

messages, printing of barcodes, and numerous other advantages.

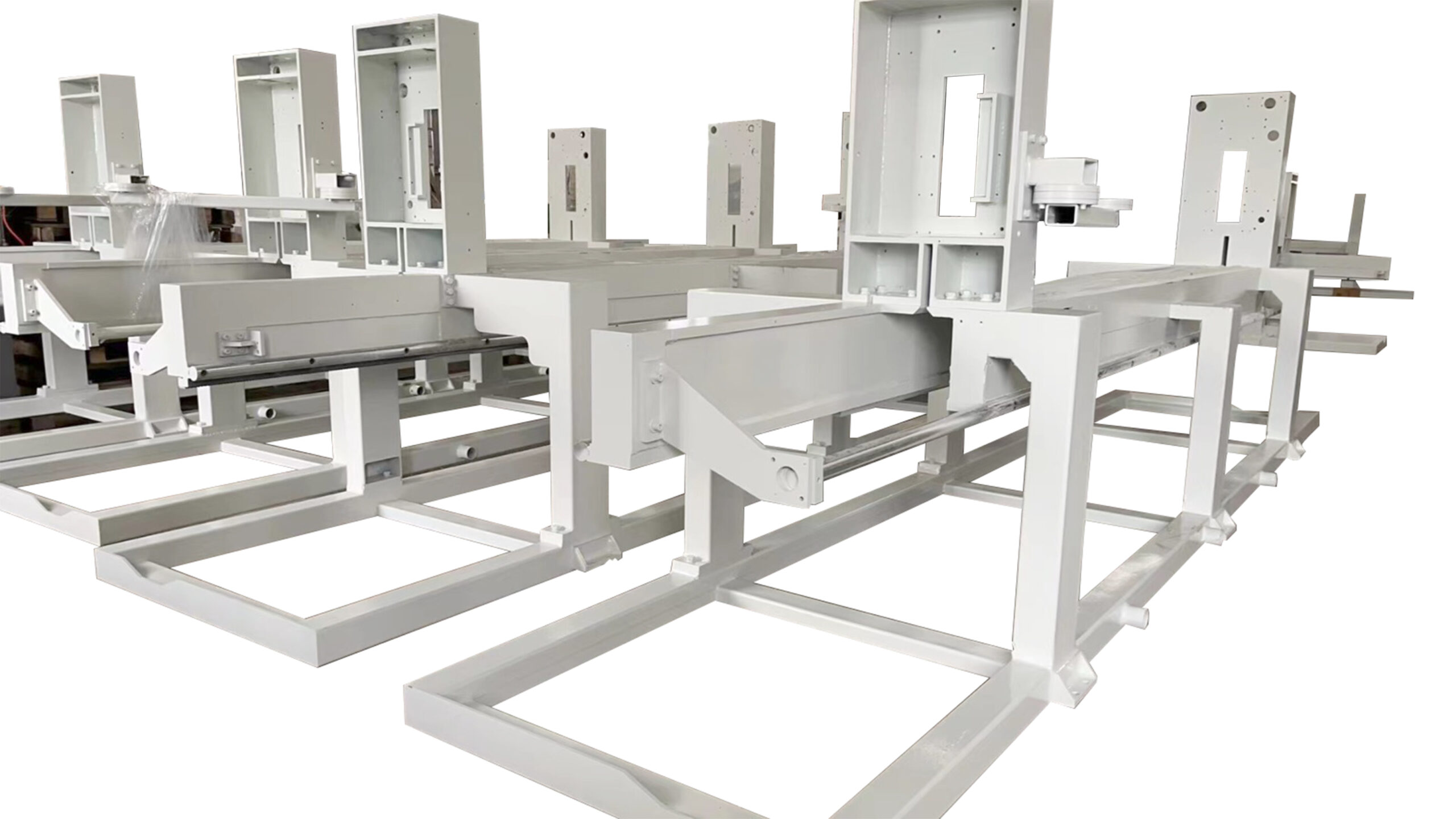

MACHINE BODY

- Adequate metal fabrication process is essential to ensure the precision and longevity of a specially designed machine body, which is constructed using high tensile strength steel.

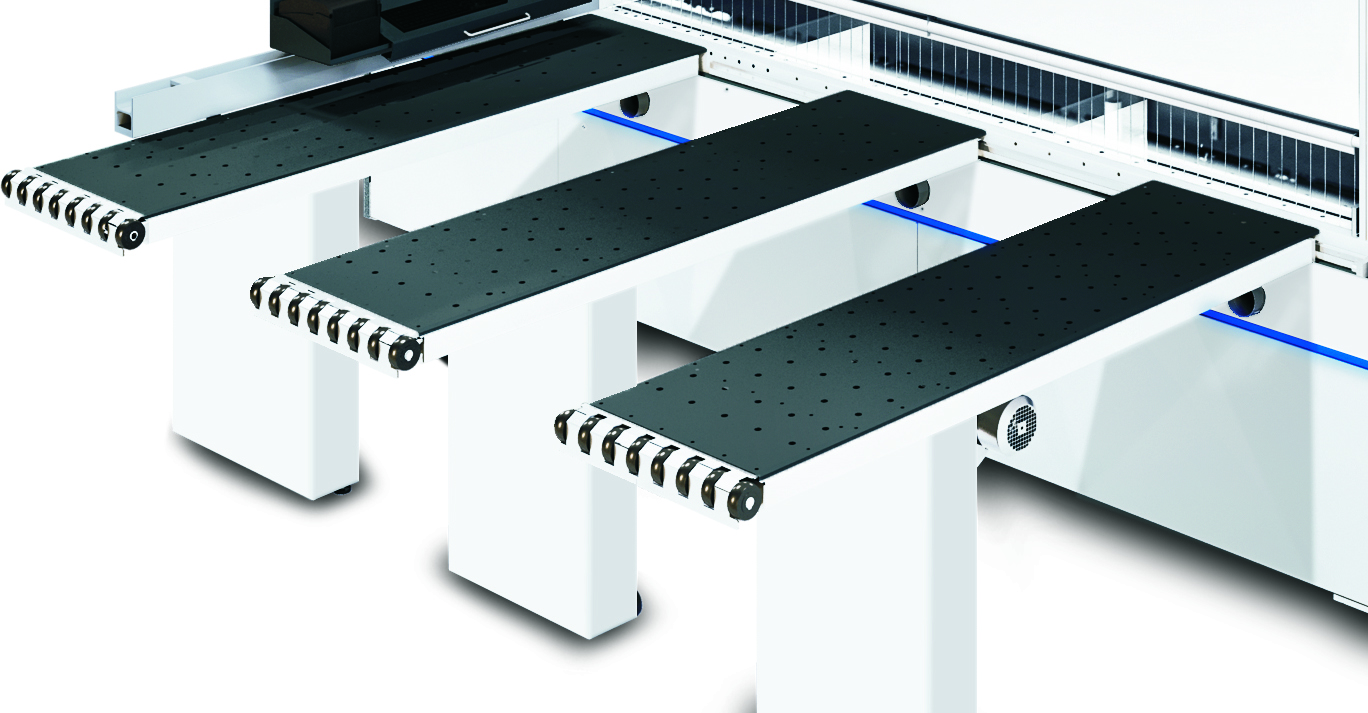

AIR FLOAT FEED TABLE

- The presence of steel balls on the table surface, along with a fan, guarantees smooth movement of panel stacks by providing constant air circulation.

- The black table plate is sturdy and resistant to wear, ensuring the optimal protection of the panel surface.

- Three pipes are linked to three float tables, and a air blower positioned beneath the table provides an ample supply of air. The flow rate is measured.

MACHINE EQUIPMENTS ( OPTIONAL )

PIANO DUST COVER

The piano dust cover is designed to offer a fully enclosed blade guard, effectively safeguarding against the dispersion of dust and debris.

AC SERVO GEAR BOX

The AC servo gear box ensures a consistent force on the rack and pinion from both sides to maintain stable option.

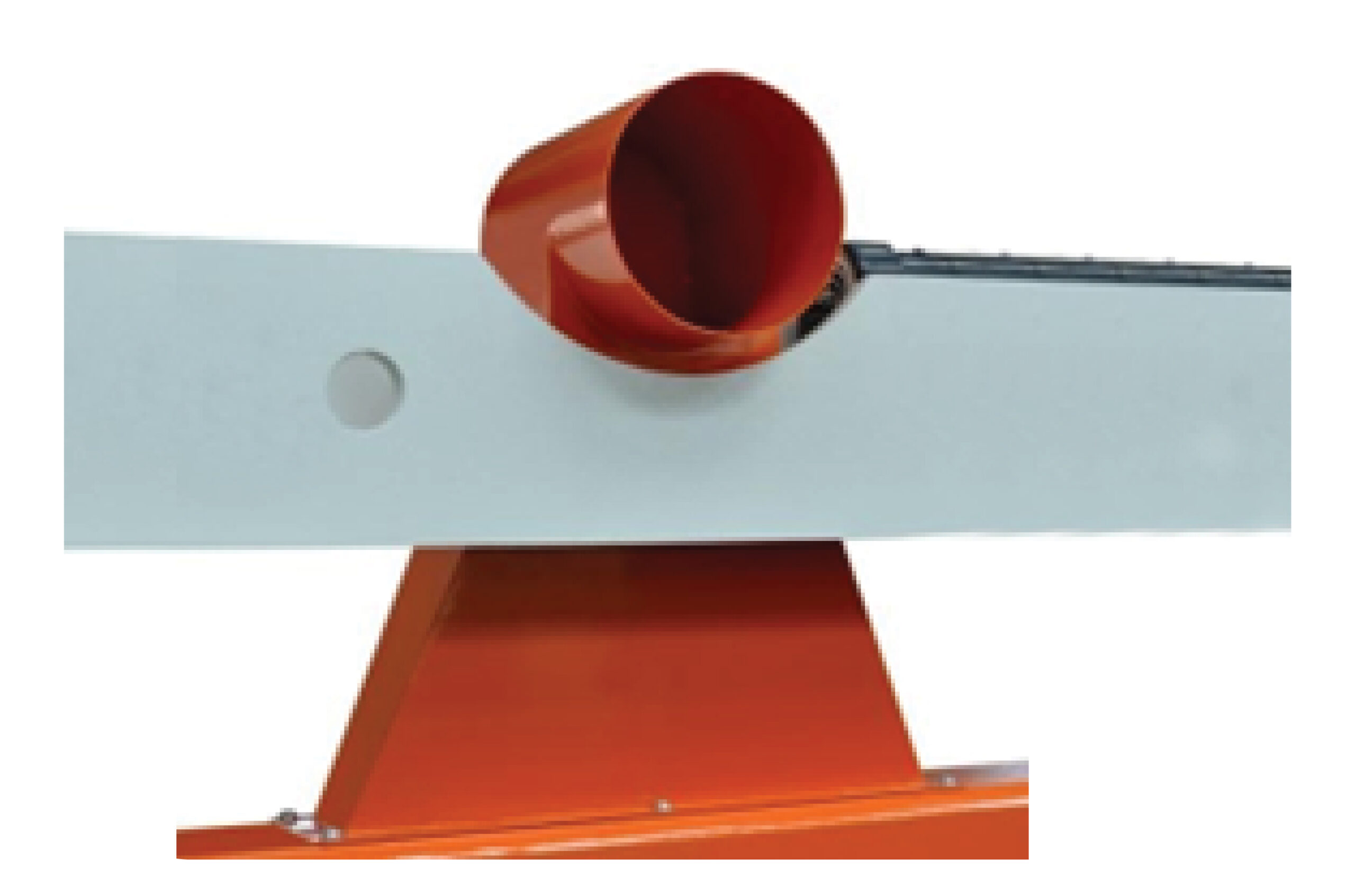

DUST COLLECTION

The top and bottom dust collectors help minimize airborne chips and dust, creating a more convenient working environment that ultimately prolongs the service life.

AUTOMATIC LUBRICATION SYSTEM

The main transmission components are automatically greased by the automatic lubrication system, thereby reducing the maintenance required by operators.

TECHNICAL SPECIFICATION

Automatic Beam Saw UBS 3200 AUTO

Maximum Production Output with Excellent Cutting of Multiple Panels

Machine Control

User-friendly HMI Coordinated with USB interface. Network Card, mouse and keyboard for easy operation English are available.Controlled by IPC, Windows operating system and Nangxing ‘s professional computer saw cutting software.

Automatic Lubrication system

The automatic lubrication system ensures smooth Operation, and reduces the possible costs of repair And maintenance.

Pressure beam

When performing cross cut.put same pressure evenly on the whole surface of the panel so as to ensure accuracy Piano type dust cover provides a completely enclosed Blade guard and prevents flying dust and chips.

Saw Unit Saw Carriage

Standardized assembly for high precision. And the height of main saw is automatic adjusted the sensor according to the thickness of panels.Guided with round guide rail on top and bottom, 22mm Thickness thick solid plate bearing type unilateral Suspension structure designed for stable movement of saw carriage.

Saw Blade

Main saw and Scoring saw by independent controls. With selected 18kw Italian main motor Up and down guided by liner sliding block.

Main Saw Blade:Ø460*Ø60

Scoring Saw Blade :Ø180*Ø45

Floating feed table

Floating feed table with steel balls reduces any scratches On panel surface and ensures transmitted smoothly.

Pressure fan under working table reduces wastage of wind wastage. 2*2.2kw=4.4kw.

Machine frame

The Steel frame welded with heavy steel plates is made by tip-top metal processing center. After heat treated and constructed, the steel frame is solid and that permits high capacity cutting.

Computer Controlled Beam Saw Machine

| Model | UBS 3200 AUTO |

|---|---|

| Saw cutting length | 3250 mm |

| Saw cutting thickness | 100 mm |

| Diameter of main saw blade | Θ 400mm |

| Diameter of main saw blade shaft | Θ 60mm |

| Revolving speed of main saw blade | 3930 r/min |

| Diameter of scoring saw blade | Θ 180mm |

| Diameter of scoring saw blade shaft | Θ 30 mm |

| Revolving speed of scoring saw blade | 6500r/min |

| Advance speed of saw base (stepless) | 9-50 m/min |

| Back speed of saw base | 100 m/min |

| Drive motor of saw base | 1 kw |

| Drive motor of main saw blade | 15 kw |

| Automatic feeding motor | 1.5 kw |

| Automatic feeding speed | 50m/min |

| Operating pressure | 5 ~ 8 kg/cm |

| Net weight of device | 62420 kg |

| External dimensions (l. x W x H) | 5830 x 6630 x 1810 mm |

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Let's talk !

Please fill out this form and relax.

Our expert executive team will reach out to you and

offer the most suitable advice according to your needs.

Please contact we would like to help you.

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.

Explore Our Most Selling Machines

Edge Bander

Hydraulic Coldpress

Panel Saw

Multi Boring