UPF 1000

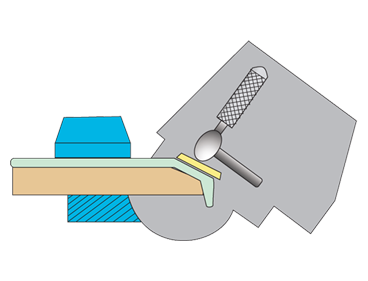

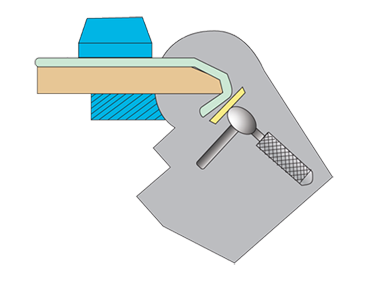

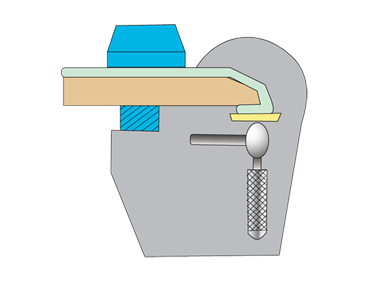

Post forming Machine is, a functional and productive machine and equipped with 180.movable and mechanical arm to

give shape laminate in any shape on

board. UPF 1000 post forming machine

guarantees precise, efficient

and productive operation.

"Perfect appearance for your Customer Satisfaction with absolutely Affordable Technology"

Salient Features

- PLC control panel which has a capacity of 15 job programs.

- Special pneumatic gauge is operated by 2 pneumatic cylinders for repetitive jobs settings.

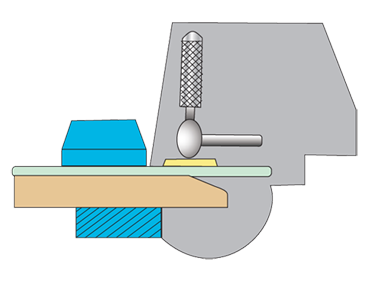

- 8 pneumatic cylinders to apply uniform pressure on job through forming heater bar assy. for effective bonding of laminate.

- Long life heater bar ground and hardened.

- Back stops facility.

- Possibility to laminate more than one small board.

- Automatic post forming cycle with variable heating time, stop and go time and holding time can be adjusted to profile.

- Drive motor with brake is provided to avoid slippage of rotary part.

- Motion of the heater bar.

- Mechanical drive control by limit switch.

- Widely use for making post form office furniture & curvature edge laminate pressing.

- Kitchen tops, desk tops, table tops, shutters cabinets, shelves cupboards, office furniture etc.

| Model | UPF1000 |

|---|---|

| Maximum length of job | 2440mm |

| Minimum length of job | 300mm |

| Job thickness range | 16mm to 125mm |

| Minimum job width | 150mm |

| Maximum heating temp | 200° C |

| Air pressure | 7kg/cm2 |

| Heating element | 1.5kw |

| Electric motor-3phase | 0.5hp |

| Control type | PLC fully automatic |

Technical

specification

"We Serve What

You Looking For"

PLC Controller

- Easy to operate.

- 15 job programmes

- Manual & Auto control

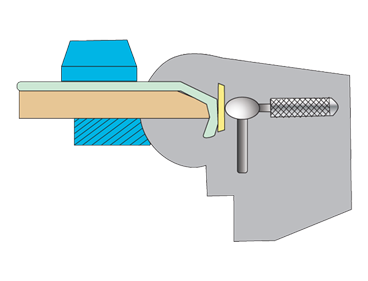

Gauge Stopper

- Special pneumatic gauge stopper with 2 cylinder for repetitive job's settin

- Gauge stopper with sensor for auto job profile

Pressure Clamp

- Pressure clamp with 3 pneumatic cylinder for proper job grip.

- Soft cotton on pressure clamp for better grip & to avoid job damage.

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.