We applied all our experience in sanding technology

to make this type machine. It's main advantage is high cost performance(good quality and affordable price), this machine is easy to adjust and maintain, our purpose is save you time and cost.

| Model | Heavy Duty Type | Standard Type |

|---|---|---|

| Contact roller diameter | 240mm | 240mm |

| Calibrating roller diameter | 210mm | 210mm |

| Working width | 40-1300mm | 40-1300mm |

| Working thickness | 2.5-150mm | 2.5-150mm |

| Feeding speed | 7-30m/min | 7-30m/min |

| First belt speed | 24m/s | 24m/s |

| Second belt speed | 18m/s | 18m/s |

| Sanding belt size | 1330x2200mm | 1330x2200mm |

| Total power | 63.62kw | 39.82kw |

| First belt motor | 37kw | 22kw |

| Second belt motor | 22kw | 15kw |

| Motor position | Outside | Inside |

| Feeding motor | 4kw | 2.2kw |

| Lift & decline motor | 0.37kw | 0.37kw |

| Brush motor | 0.25kw | 0.25kw |

| Working pressure | 0.4-0.8 Mpa | 0.4-0.8 Mpa |

| Compressed air consumption | 1.5CBM/min | 1.5CBM/min |

| Overall dimension | 2300x2650x2120mm | 2300x2000x2120mm |

| Weight | 4000kgs | 3600kgs |

Technical

specification

"We Serve What

You Looking For"

"Perfect appearance for your Customer Satisfaction with absolutely Affordable Technology"

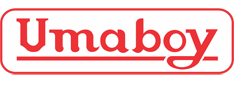

Pressure Units

- Pressure units to hold the work pieces on the conveyor belt; are positioned in front and rear of each working unit; the press rollers with springs to compensate panel thickness difference.

- Pressure units are exposed on both ends, easy to adjust.

Feed System

- Feed table is built in granite with tolerance of planarity within 0.05mm; table surface fine-grinded to avoid wear of the internal side of the feed belt; the granite feed table is never distortion.

- Conveyor belt with surface in rubber at appropriate hardness; top profile according to operation requirement. Drive unit with motor and reducer, feed speed variable in continuous from 7m/min to 30m/min.

- Feed table extension in machine front side with steel idle rollers.

1st working unit

- Working unit with diameter 240mm steel sanding roller complete with: sanding belt tension unit; electronic oscillation; dust hood; safety systems.

- Sanding roller with helicoidal grooves for cooling. Motor with one speed of rotation.

2nd working unit

- Working unit is a combination of rubber roller and pad, with alloy rack, felt, graphite cloth complete with sanding belt tension unit; electronic oscillation; dust hood; safety systems.

- Rubber roller is diameter 210mm and hardness 85 shore. Sanding pad can be adjusted up and down easily. Motor with one speed of rotation. (Air pad is available)

Optional Device

- Air jet blower for sanding belt cleaning.

- Italy Cigo conveyor belt

- Vacuume feed table

- Customer other's request according to the fact.

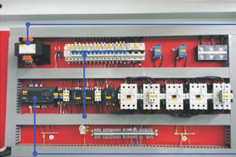

Electric Plant

- Electric plant in the front of machine, includes a main switch, PLC, contactor, breaker and so on.

- Electric plant built on standard CE rules.

- Electric parts adopt Schneider brand.

Electric Plant

- Pneumatic plant complete with oil/air nebulizer, solenoid valve air pressure relay and so on. Pneumatic parts adopt Airtac and Chelic brand.

Note: Technical specifications may be changed without any prior notice. Product images are just for the reference.